Best CNC Laser Cutting Engraving and Marking Machines

CNC Laser Machines are high-precision processing equipment that integrates laser technology and computer numerical control (CNC) technology. They are suitable for various industries such as metal cutting, plastic and acrylic processing, wood carving, stone, textile materials, and more. These machines are widely used in metalworking, automotive manufacturing, electronics, advertising, aerospace, artwork, gifts, packaging, and other industries.

The laser beam concentrates high energy to cut, weld, engrave, and process materials. Compared with traditional mechanical processing, laser cutting offers advantages such as high precision, smooth cutting surfaces, fast processing speed, and minimal material waste.

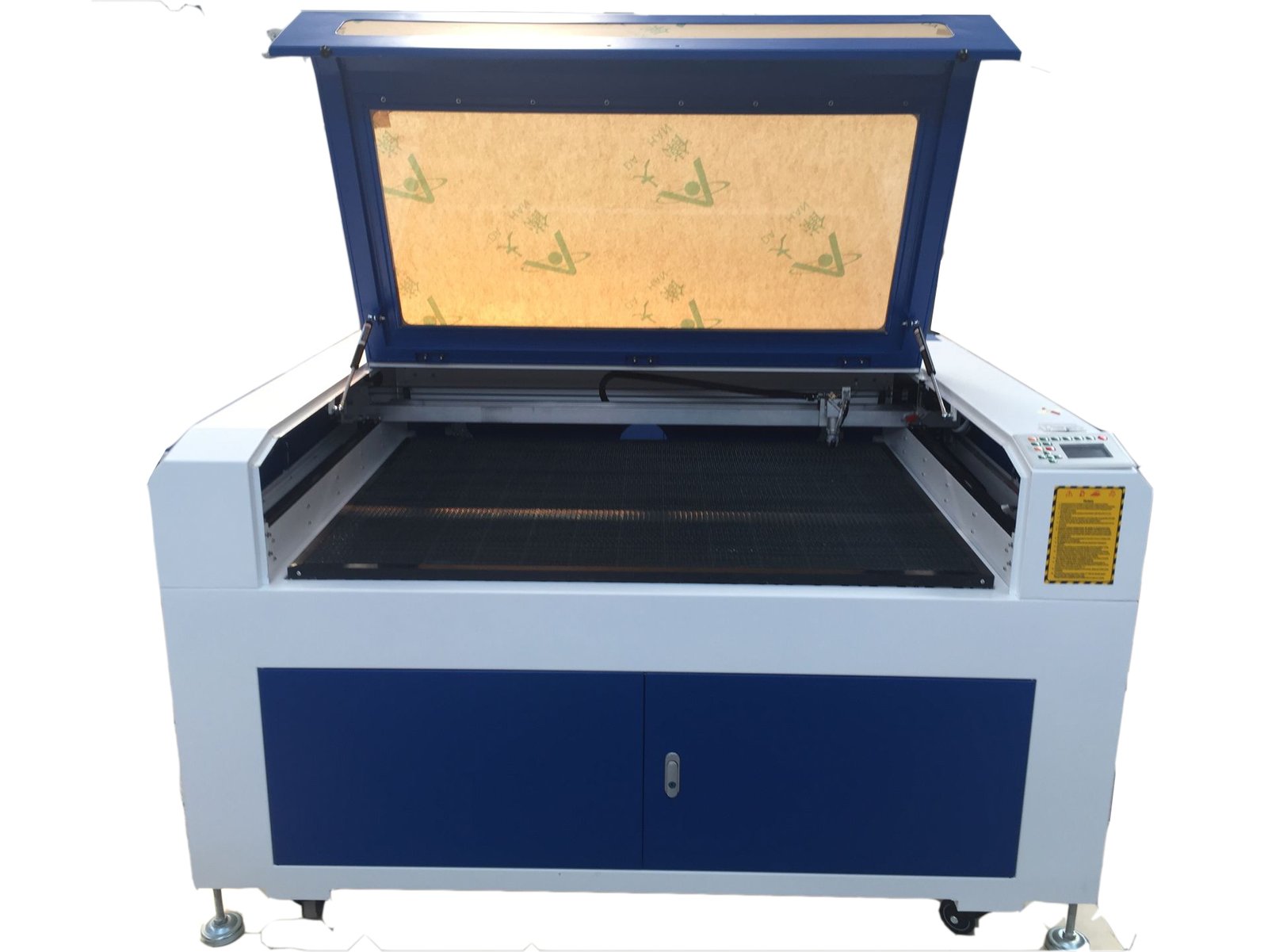

VERSIGN CNC manufactures perfect, high-efficiency CNC fiber laser metal cutting machines, CO2 laser engraving machines, CO2 cutting machines, fiber laser marking machines, fiber laser welding machines, and cleaning machines. We also offer custom laser equipment tailored to meet the specific needs of our customers.

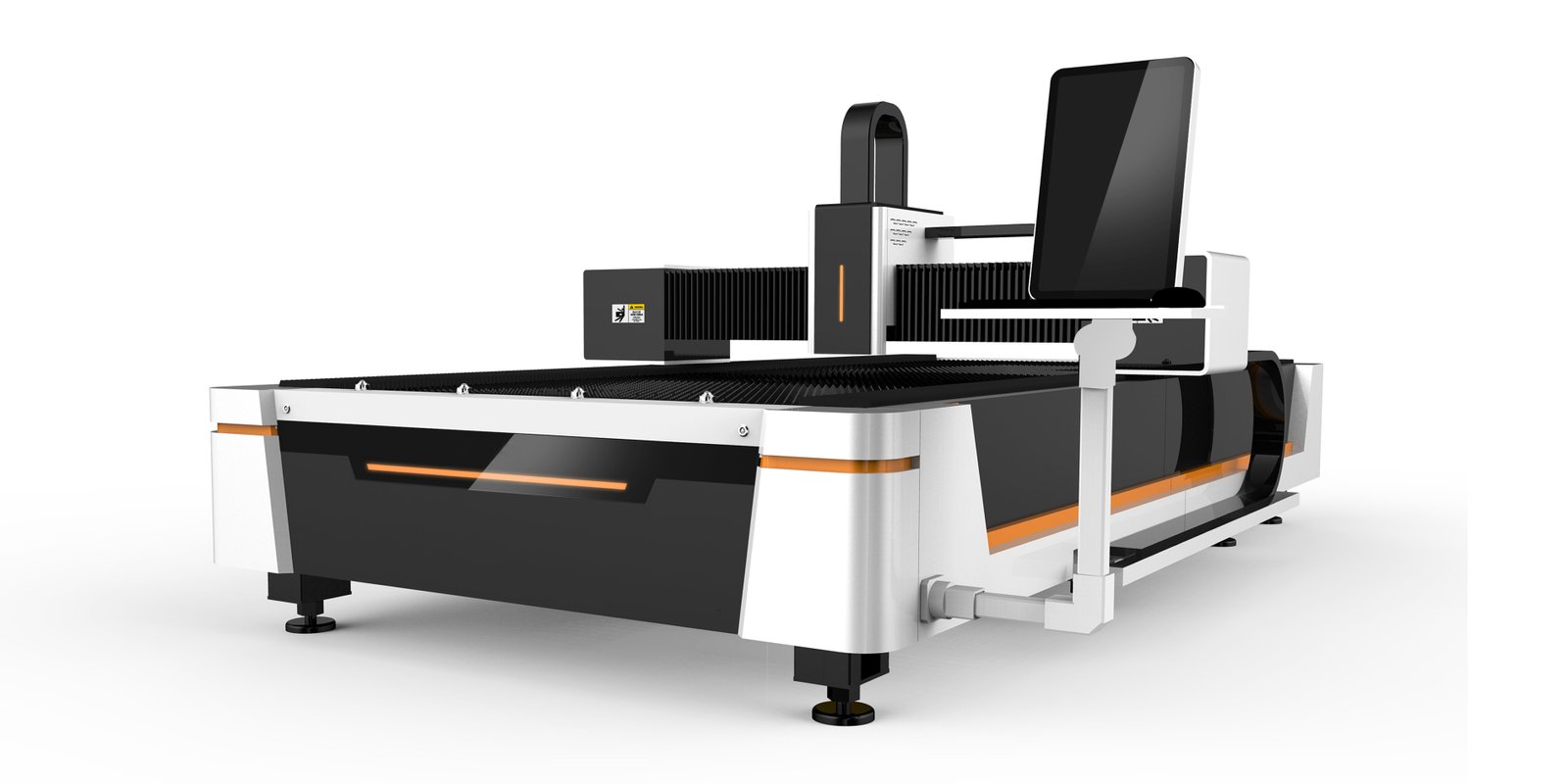

CNC Fiber Optic Laser Metal Cutting Machines

A fiber laser cutting machine is a high-precision metal cutting industrial device capable of cutting various materials, including mild steel, stainless steel, aluminum, brass, copper, and even some non-metals like plastics and ceramics. The core component of the fiber laser is the laser generator, where the laser gain medium is a fiber optic material. This fiber contains rare-earth elements, such as erbium (Er) and ytterbium (Yb), which absorb energy and emit laser light.

- High Precision: Fiber laser beams have excellent focusability, allowing for precise cuts with minimal thermal distortion. Precision can reach 0.01mm or even lower.

- Superior Beam Quality: The laser generated by fiber lasers is more focused, with higher power density, resulting in cleaner cuts and reducing post-processing requirements.

- High Efficiency: Fiber lasers are more efficient than traditional CO2 lasers, requiring less energy for the same output and cutting at higher speeds, making them ideal for mass production.

- Low Operating Costs: Due to their high efficiency and low maintenance requirements, fiber laser cutting machines generally have lower operational costs compared to other cutting methods.

- Wide Material Compatibility: Fiber laser cutting machines can cut a wide variety of materials, including mild steel, stainless steel, aluminum, brass, copper, and even non-metals like plastics and ceramics.

- Minimal Waste: The high precision of fiber laser cutting minimizes material waste, making it an environmentally friendly choice.

- Long Service Life: Compared to other metal cutting methods, fiber lasers have a longer lifespan with fewer wear-and-tear parts over time, ensuring durability and consistent performance. A fiber laser source working life is up to 100,000 hours or more.

- Auto-Focus: Many modern fiber laser cutting machines are equipped with auto-focus systems, allowing the machine to automatically adapt to different materials and thicknesses without manual intervention.

- Speed: Fiber lasers operate at high speeds, reducing processing time and improving productivity.