Integrated Sheet Plate and Tube CO2 Laser Cutting Machine

Price: $4,200.00

Brand: Versign CNC

In Stock

Model:SKU: V-PC1530R

Whether your focus is high-volume production or custom metalwork, this all-in-one plasma cutter ensures precision, speed, and reliability for a wide range of applications.

Inquire NowOverview

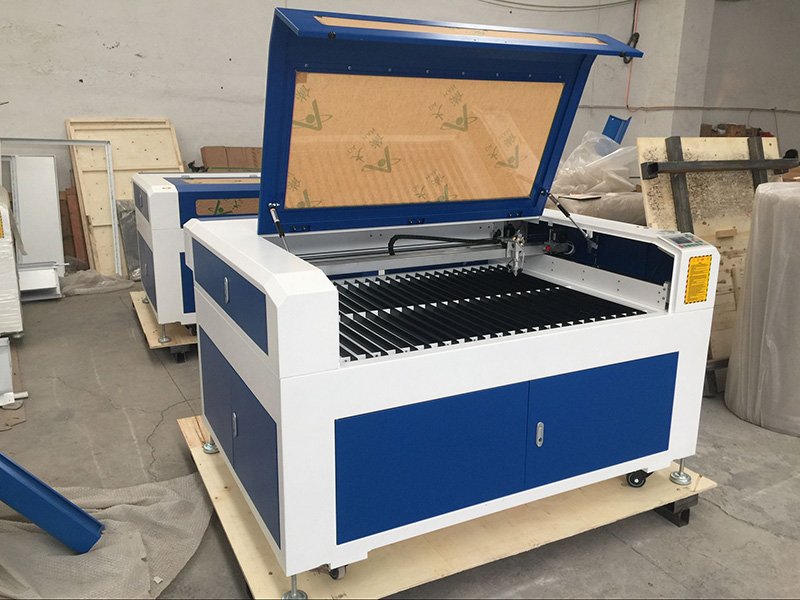

The Sheets and Tube CO2 Laser Cutting Machine is a versatile and efficient solution for both cutting and engraving applications. Equipped with a high-precision laser tube and an integrated honeycomb working platform, it delivers excellent cutting performance and fine engraving details across a wide variety of materials.

This machine supports processing of both flat sheet materials (such as wood, acrylic, MDF, and leather) and cylindrical objects (such as pen holders, tubes, and cups). With its rotary attachment, users can easily switch between sheet cutting and cylindrical engraving, achieving more creative and complex designs.

The standard working area is 1300 × 900 mm, with a 30 cm liftable platform to accommodate thicker materials or irregular objects. For businesses requiring flexibility, custom sizes and configurations are available to match specific production needs.

Whether used for decorative products, personalized gifts, furniture components, or craft production, the Sheets and Tube CO2 Laser Cutting Machine ensures high precision, smooth edges, and consistent results. It is an ideal choice for workshops, sign makers, furniture factories, and creative studios.

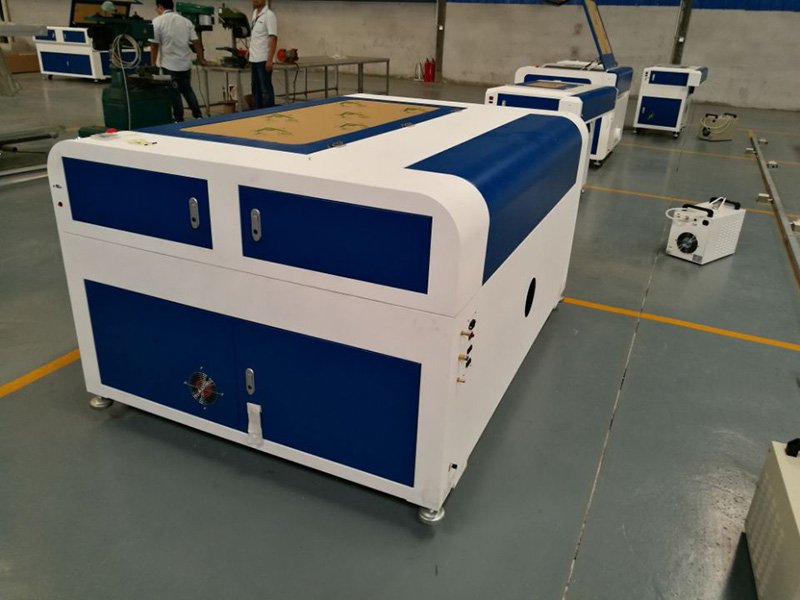

Photos

Here are some images of our Sheets and Tube CO2 Laser Cutting Machine, showing its robust design and versatile working platform for both sheets and cylindrical materials.

Technical Parameters

Below are the detailed specifications for the U-L1390 Sheets and Tube CO2 Laser Cutting Machine.

| Working area | 1300 x 900mm rotary customized |

|---|---|

| Laser power | 80W / 100W, Reci CO2 sealed laser tube, water-cooling |

| Engraving speed | 0 – 60000 mm/min |

| Cutting speed | 0 – 30000 mm/min |

| Laser output | 1–100% software setting |

| Resetting positioning accuracy | ≤ ±0.01 mm |

| Power supply | 220V / 50–60Hz |

| Operating temperature | 0 – 45°C |

| Operating humidity | 5 – 95% |

| Control system | DSP with USB port |

| Min. shaping character | English 1.0 x 1.0mm |

| Graphic format supported | BMP, PLT, DST, DXF, AI |

| Software supported | CorelDraw, AutoCAD, Lasercut |

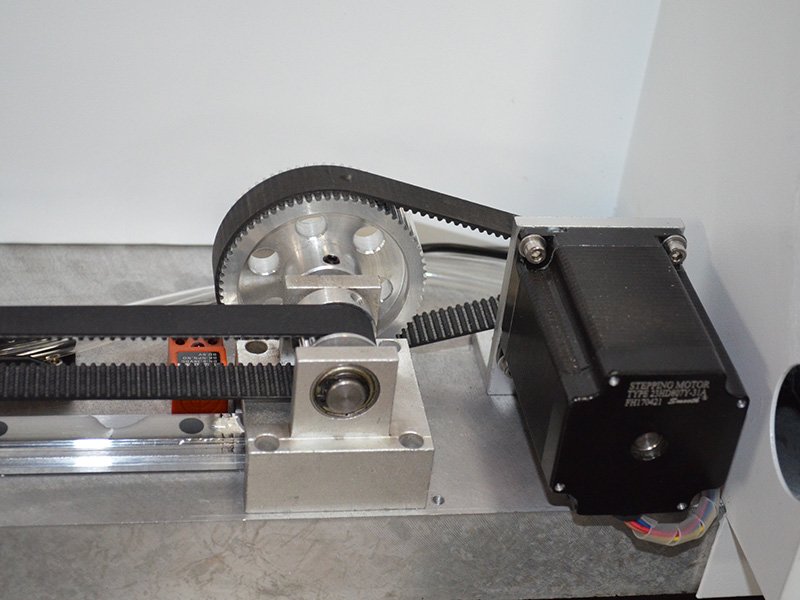

| Driving system | Stepper motor |

| Equipment dimension | 1780 x 1300 x 1000 mm |

| Packing dimension | 1880 x 1400 x 1200 mm |

| Gross weight | 450 kg |

Applicable Materials

- Engrave: Wood, acrylic, stone, glass, garment, paper, cloth, rubber, leather, etc.

- Cut: Wood, acrylic, rubber, leather, cloth, paper, MDF, etc.

Standard Configuration

- 80W / 100W laser tube

- DSP control and USB port

- Water chiller CW5200 model

- Exhaust fan and wind pipe

- Air pump

- Knife worktable for hard materials (acrylic, MDF, etc.)

- Red dot pointer

Machine Photos

Here are some detailed photos of the Sheets and Tube CO2 Laser Cutting Machine, showing different angles, working conditions, and structural highlights.

Advanced Features

- Adaptive Cutting Technology: Equipped with adaptive THC (Torch Height Controller), this machine ensures smooth operations by adjusting to varying material thicknesses, minimizing wear on the torch and enhancing edge quality.

- 360° Tube Rotation Cutting: Supports full 360° rotation for tubular materials, allowing intricate patterns and custom shapes—ideal for structural and decorative applications.

- High-Definition Plasma Cutting (HD Plasma): Delivers fine cuts with minimal dross, reducing the need for post-processing and improving overall production efficiency.

- Multi-Layer Material Handling: Capable of cutting stacked sheets simultaneously, accelerating batch processing for large-scale projects.

- Dynamic Axis Compensation: Adjusts for thermal deformation in real-time, ensuring dimensional accuracy during extended cutting sessions.

- Remote Monitoring and Control: Built-in IoT-enabled monitoring allows users to oversee operations remotely, receive performance reports, and schedule maintenance.

-

Enhanced Safety Features:

- Bullseye Rollers: Ensure smooth and stable movement of metal sheets and tubes, reducing the risk of material slipping or jamming.

- Red Dot Positioning: Simplifies material alignment with a laser-guided red light system for precise starting points.

- Anti-Collision Sensors: Detect obstacles and stop operations to protect operators and equipment.

- Energy-Efficient Design: Reduces energy consumption with advanced plasma power sources while maintaining high cutting performance.

- Ergonomic Control Panel: Features a touchscreen interface, shortcut keys, and real-time visualizations for intuitive operation.