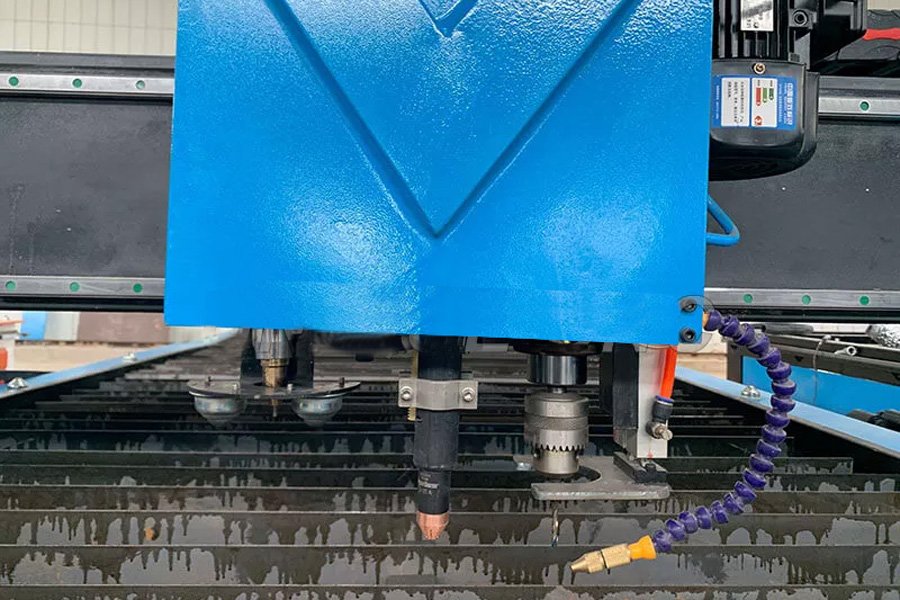

CNC Plasma Cutting, Drilling & Marking Integrated Machine

Price: $9,250.00

Brand: Versign CNC

In Stock

Model:SKU: V-PC1530DM

Our CNC Plasma Cutting, Drilling & Marking Integrated Machine is an all-in-one solution for high-speed, precise metal processing. This versatile machine not only delivers rapid plasma cutting but also excels in drilling and marking, making it an essential tool for a wide range of industrial applications. By combining multiple functions into one machine, it significantly enhances processing efficiency, reduces production time, and lowers overall equipment investment costs. Perfect for manufacturers looking to streamline operations, this machine maximizes productivity while maintaining top-notch quality and accuracy.

Inquire NowOverview

Our CNC Plasma Cutting, Drilling & Marking Integrated Machine is an all-in-one solution for high-speed, precise metal processing. This versatile machine not only delivers rapid plasma cutting but also excels in drilling and marking, making it an essential tool for a wide range of industrial applications. By combining multiple functions into one machine, it significantly enhances processing efficiency, reduces production time, and lowers overall equipment investment costs. Perfect for manufacturers looking to streamline operations, this machine maximizes productivity while maintaining top-notch quality and accuracy.

The standard table size of this machine is 5x10 feet (150x300 cm), making it suitable for most industrial needs. Additionally, customizable cutting dimensions are available, providing greater flexibility for a wide range of applications and expanding its usability across diverse projects.

Equipped with optional inverter plasma power sources ranging from 63A to 400A, along with flame cutting capabilities, this machine achieves cutting thicknesses of up to 200mm, catering to both light and heavy-duty metal processing needs.

How It Works

Experience the seamless integration of cutting-edge technologies with our CNC Plasma Cutting, Drilling & Marking Integrated Machine. Here's how it operates:

Plasma CNC Cutting

A high-temperature plasma arc precisely melts and cuts through metal, enabling fast and accurate fabrication of complex shapes.

Drilling

The integrated drilling system ensures precise hole creation with adjustable diameters, ideal for assembly preparation and customization.

Marking

High-precision marking capabilities engrave part numbers, guidelines, or custom designs for lasting clarity and identification.

Advanced Features

Discover the cutting-edge advantages of our CNC Plasma Cutting, Drilling & Marking Integrated Machine, designed to outperform competitors.

Three-in-One Functionality

Combines cutting, drilling, and marking in a single platform, saving space, time, and costs.

Customizable Configurations

Supports plasma power from 63A to 400A and flame cutting for up to 200mm thickness.

Inverter Technology

We use inverter technology, where a high-frequency inverter converts AC power into DC power, and then a high-frequency switch controls the conversion of DC into adjustable pulse current. This design not only improves the stability and cutting quality of the power supply but also significantly enhances energy efficiency and operational performance. Compared to traditional linear power supplies, inverter-based systems are lighter, more compact, and can provide higher power density and efficiency.

Durable and Maintenance-Friendly Design

Robust structure ensures long-term performance and easy maintenance.

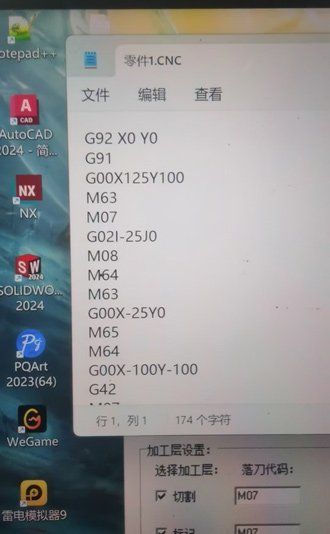

User-Friendly CNC System

Designed with an intuitive and user-friendly interface, this machine offers seamless operation and effortless programming. Whether you're a seasoned professional or a novice operator, the intuitive controls simplify setup and customization, allowing for quick adaptation to different tasks. With clear, easy-to-navigate menus and real-time feedback, it ensures a smooth workflow, minimizing the learning curve and maximizing productivity. The system is designed to enhance the operator's experience, making even complex programming tasks feel effortless and efficient.

Enhanced Marking Technology

Supports engraving and etching for clear, permanent markings.

High-Frequency Start and Anti-Interference Design

We use high-frequency arc-starting technology to ignite the arc without making contact with the workpiece. This process is crucial for the stability and efficiency of the equipment, especially in applications requiring precise cutting. In addition, modern plasma power supplies have made significant improvements in anti-interference capabilities. They employ multi-stage filtering and shielding designs to effectively reduce electromagnetic interference between the power supply and other equipment, ensuring a smooth cutting process.

Energy-Efficient and Eco-Friendly

Optimized systems reduce energy consumption and environmental impact.

Details

Explore the customizable and advanced features of our CNC Plasma Cutting, Drilling & Marking Integrated Machine. This machine is a comprehensive all-in-one solution meticulously designed based on years of experience in the metal processing industry and the diverse needs of our clients. Combining flawless machine design, top-quality components, and our unwavering dedication to craftsmanship, we proudly present this flagship product tailored to elevate efficiency and precision in every application.

- Color Options: Default color is blue, but customization options are available, including the striking Mars Green.

- Table Size: Standard 5x10 ft (150x300 cm) table size, with custom dimensions available for specific project needs.

- Optional Rotary Axis: Features a four-jaw chuck capable of clamping large and heavy workpieces for advanced operations.

- StarFire Control System: Equipped with the StarFire CNC system for precise and reliable performance.

- User-Friendly StarCAM Software: Includes StarCAM software for simplified operation and efficient workflow management.

- High-Quality Components: Built with branded components, including imported linear guides and rack systems for enhanced durability.

- Integrated Dust Collection: Advanced dust extraction system ensures a clean working environment and protects internal components.

- Automatic Torch Height Control: Maintains optimal cutting distance to ensure consistent cutting quality across various materials.

- Customizable Tool Heads: Supports various tool attachments for increased versatility in cutting, drilling, and marking applications.

- Energy-Saving Design: Optimized power consumption with inverter technology, reducing operational costs without compromising performance.

Specifications

| Feature | Specification |

|---|---|

| Flat Cutting Working Area | 1500mm x 3000mm(5x10ft) or customized |

| Z Working Area | 150mm |

| Working Voltage | 380V/220V Three Phases 50-60HZ |

| Reposition Precision | 0.02mm |

| Processing Precision | 0.1mm |

| Maximum Cutting Speed | 12000mm/min |

| Cutting Thickness | 0-200mm |

| Drill thickness | 20mm |

| Rotary Diameter | 200/300/400mm |

| Plasma Power Supply | LGK/Hypertherm |

| Control System | Starfire |

| Motors | Stepper Motors / Servo Motors |

| Software | Starcam |

| Total Power | Around 20KW |

| Overall Dimension | 4020 x 2860 x 1550mm |

| Net/Gross Weight | 2400/2550 kg |

Note: The machine specifications may change due to future upgrades or improvements. Please consult with us for the most up-to-date information.