Overview

1KW 2KW 3KW Auto Focus Table Fiber Laser Cutting Machine

The 1KW, 2KW, and 3KW Auto Focus Table Fiber Laser Cutting Machines provide high precision and exceptional performance for industrial metal cutting applications, support flying cutting. They are designed to handle various metals, including stainless steel, carbon steel, aluminum, brass, and copper, ensuring precise, clean cuts with each use.

Featuring an auto-focus laser head, these machines automatically adjust the focal point for optimal quality across different material thicknesses, eliminating the need for manual intervention. The robust table structure guarantees stability and precision, ideal for high-demand production environments.

With options ranging from 1KW to 3KW, these fiber laser cutters cater to diverse production needs, delivering a balance of power, speed, and accuracy for both intricate and heavy-duty tasks.

Advanced Features

High-Power Cutting Options

Versign CNC Auto Focus Table Fiber Laser Cutting Machines are available in 1KW, 2KW, and 3KW power options, providing flexibility for different cutting needs. These power levels allow precise cutting for materials ranging from thin sheet metals to thicker, industrial-grade metals.

Auto-Focus Laser Head

The auto-focus laser head adjusts automatically to the optimal focus point, enhancing cutting quality and efficiency. This feature ensures a smooth, accurate cut across varying material thicknesses, saving time and reducing the need for manual adjustments.

Durable and Stable Table Structure

Built with a reinforced table design, the machine minimizes vibrations and enhances stability during high-speed operations. This stability ensures high-precision cuts and prolongs the machine's lifespan, even under continuous, demanding use.

- Heat Treatment Processes: The steel frames undergo annealing at temperatures over 600°C, effectively relieving internal stresses to prevent distortion, even with continuous use.

- Very Stiff and Stable Base: The frame is engineered for exceptional rigidity, ensuring precise and accurate cutting performance.

- High-Precision Electric Welding: The frames are welded using high-precision electric welding techniques, ensuring a strong and reliable structure.

- Advanced Manufacturing: We use high-tech boring machines to create parts with extreme precision, reducing vibrations and improving accuracy.

- Reinforced Structure: The machine frames are reinforced to minimize twists and deformation, ensuring long-term stability. The robust frame is securely connected to the chassis using steel bars, providing additional support and strength.

Aluminium Gantry Structure

Our Versign CNC® machines feature a high-tech aluminum crossbeam, which offers a number of performance advantages:

- Lightweight and Rigid Design: The aluminum gantry is cast using a specially designed 10-tonne steel mold, providing superior rigidity while being 50% lighter than traditional iron gantries. This reduction in weight results in higher acceleration and reduced inertia, improving the machine's overall efficiency and performance.

- Laser Interferometer Precision: To ensure the utmost accuracy, we use a German-made laser interferometer for measurement and adjustment. This system meticulously measures and adjusts the linear operation precision of the machine, achieving a mechanical structure accuracy of up to 0.01mm.

Advanced CNC Control System

Equipped with an intuitive CNC control system, this machine simplifies complex cutting operations and improves efficiency. The user-friendly interface and programming features make it easy to operate, enhancing productivity for operators of all skill levels.

Customizable Work Area

While the standard work area is 1500 x 3000 mm (4.9 x 9.8 ft), we offer customization options to fit specific production needs, allowing greater versatility for various project sizes and types.

Environmentally Friendly Operation

Fiber laser technology consumes less energy compared to traditional CO2 lasers and produces minimal waste. This eco-friendly feature helps to reduce operational costs and the environmental impact, aligning with sustainable manufacturing practices.

Precision and Efficiency

With cutting speeds reaching up to 30m/min, our fiber laser cutters maximize productivity without compromising quality, making them ideal for large-scale production tasks where time and precision are critical.

Flying Cutting Technology

Our fiber laser cutting machines support Flying Cutting, allowing for continuous cutting while the material moves. This ensures high-speed, precise cutting without stopping, improving overall efficiency and production speed. With real-time adjustments to the laser focus, Flying Cutting enables accurate results, even at high speeds. This technology is ideal for mass production, reducing downtime and material waste.

Product Details

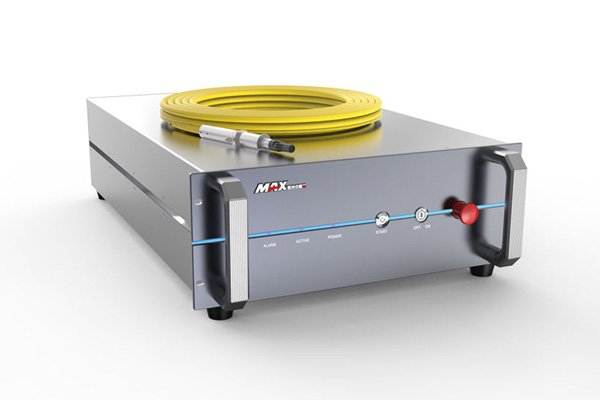

MAX Brand Fiber Laser Source

The MAX fiber laser source is one of the most stable and efficient brands in the industry, available in 1-6KW options. It is equipped with the new generation of Single Module 2000W-3000W Fiber Lasers, combining high power, compact size, superior beam quality, and high light conversion efficiency. This laser source is perfect for precision processing, 3C product welding, and cutting high-reflective materials. It is suitable for remote processing, high-frequency laser cutting, and clean surface cutting.

We also offer optional Raycus and IPG laser sources to cater to different cutting needs.

Raytools Laser Head

The Raytools laser head is made in Switzerland and is known for its classic design and exceptional performance. It features a 35mm clear aperture that effectively reduces stray light interference, ensuring high cutting quality and long service life. Key features include:

- Motorized adjustment of lens position

- Anti-collision system included

- Adjust box EG 8030, focal lens 200mm, glass protection, 3 nozzles

- Collimator at 90º focal 100mm

- Variety of optical interfaces for compatibility with multiple fiber lasers

- Compact design and motorized protection windows

- Auto focus ranges from +10 to -12mm with an accuracy of 0.05mm

- Drawer-type lens mount for quick and easy access to the cover glass

- Automatic adjustment of the focus and depth of the laser beam via the "MZ - collimator module"

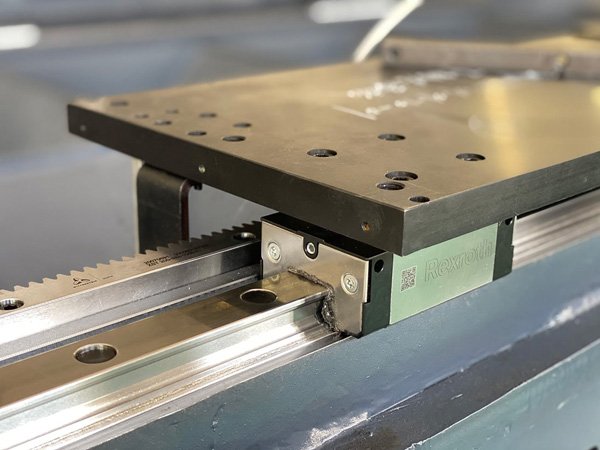

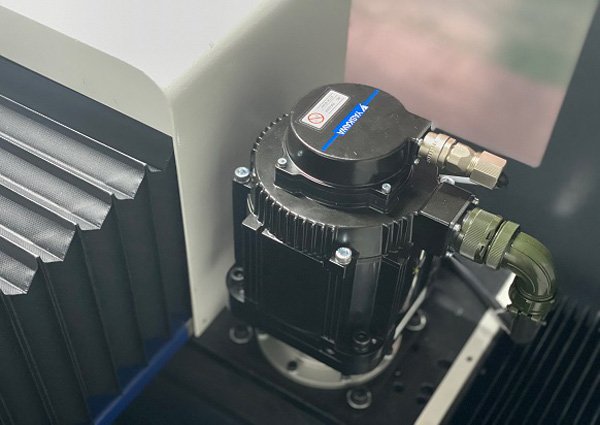

Motion Components

The motion system is powered by full servo motors, with the most suitable Delta brand motors from Taiwan, known for their low failure rates and market validation. The motion system also features:

- German YYC racks and pinions with high precision two-way, hardened helical racks

- Low running clearance for achieving very high acceleration and speeds synchronized at 170 m/min

- Optional TBI, HWIN, and other brands for customization

CypCut Control System

The CypCut CNC system is designed to enhance operational efficiency and ease of use. Key features include:

- 22” high resolution color TFT (Optional touch screen control)

- Highly dynamic servo drive technology

- Integrated retention brake control

- Automatic adaptation of parameters

- Adjustable error reaction

- Motor feedback for absolute position registration

- Supports both pipe cutting and flat cutting with the same programming

- Multi-language support including English, French, Spanish, and more

Gas Supply System

The gas supply system plays a crucial role in maintaining both the cleanliness of the machine and the working environment. It effectively flows away cutting dust and fumes, ensuring a cleaner workspace and preventing the buildup of contaminants that could affect the machine's performance. By maintaining a clean operating environment, the system helps to extend the lifespan of the equipment and improve cutting quality.

Full-Automatic Lubrication System

Our fiber laser cutting machine is equipped with a full-automatic lubrication system designed to ensure smooth operation and minimize wear on moving parts. This system automatically applies the right amount of lubricant to key components, reducing friction and ensuring efficient performance. By maintaining optimal lubrication levels, the system helps prevent overheating, extends the lifespan of the machine, and reduces the need for manual maintenance. This feature enhances the machine's reliability, ensuring it operates at peak efficiency for extended periods of time with minimal downtime.

Water Chiller

Our water chiller offers precise temperature control with an accuracy of ±0.1°C, ensuring optimal performance and preventing overheating of the system.

Optional Exchange Platform

The machine offers an optional exchange platform, allowing for rapid material change. In just 10 seconds, you can switch to a new metal material, significantly improving productivity.

Specifications

| Specification | Details |

|---|---|

| Flat Cutting Working Area | 3000mm x 1500mm |

| Laser Type | Fiber Laser Generator |

| Laser Power | 1KW, 2KW, 3KW |

| Transmission System | Gantry Double-Drive Structure |

| Lubrication System | Full-Automatic |

| Maximum Speed | 150m/min |

| Maximum Accelerated Speed | 1.5G |

| Reposition Accuracy | ±0.03mm/1000mm |

| Graphic Format Supported | CAD, DXF (etc.) |

| Working Environment | Temperature: 0-60℃, Humidity: ≤80%, No Condensation |

| Total Power | Around 20KW |

| Overall Dimension | 7750 x 3290 x 1600mm |

| Position Accuracy | ±0.02mm/1000mm |

| Auto Focus | Yes |

Note: The machine specifications may change due to future upgrades or improvements. Please consult with us for the most up-to-date information.

Cutting Thickness (2KW Fiber Laser)

| Material | Max Cutting Thickness (2KW) |

|---|---|

| Carbon Steel | 20mm |

| Stainless Steel | 8mm |

| Aluminum Plate | 6mm |

| Copper | 6mm |

Note: The cutting thicknesses listed above are based on the 2KW fiber laser. Cutting thickness may vary depending on different laser power options (1KW - 4KW). For detailed specifications, please refer to the PDF below.

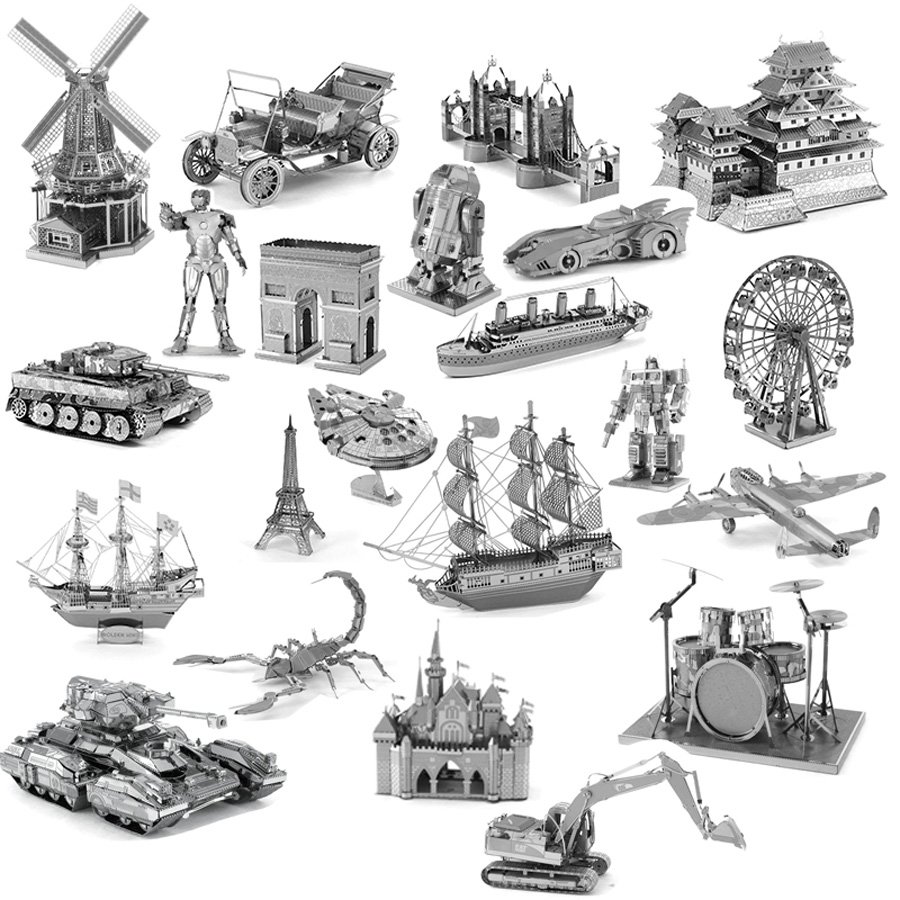

Applications of Fiber Laser Cutting Machines

Versign CNC Auto Focus Table Fiber laser cutting machines are widely used across various industries due to their precision, speed, and versatility. Below are some key applications:

Metal Fabrication

Ideal for cutting sheet metals like carbon steel, stainless steel, and aluminum. Fiber lasers offer high precision and fast cutting, making them popular in manufacturing and metalworking.

Automotive Industry

Used for cutting and shaping car parts, exhaust systems, and other automotive components with high accuracy, speed, and minimal material waste.

Aerospace

Precision cutting of lightweight alloys (like titanium and aluminum) for parts used in aircraft, ensuring minimal distortion and high quality.

Electronics

Used for cutting and engraving circuit boards, heat sinks, and enclosures, where high precision is required for tiny and delicate components.

Signage and Advertising

Laser cutting of custom signs, logos, and intricate designs in metal, acrylic, and wood. Ideal for both large-scale and detailed custom jobs.

Medical Devices

Fiber lasers are used to cut surgical instruments, implants, and other medical parts with high accuracy and minimal heat-affected zones.

Jewelry and Consumer Goods

Enables precision cutting and engraving of jewelry, personalized gifts, and decorative items with intricate designs on metal and other materials.

Renewable Energy

Fiber lasers are employed in the production of solar panel frames and wind turbine parts, offering fast, precise cuts in materials like steel and aluminum.