Small CNC Router for starters

Overview

The CNC Router for Engraving Musical Instruments is a highly versatile machine designed to meet the demanding needs of musical instrument manufacturers, like violin, piano, guitar, glute, pipa, oboe. It features advanced capabilities, including:

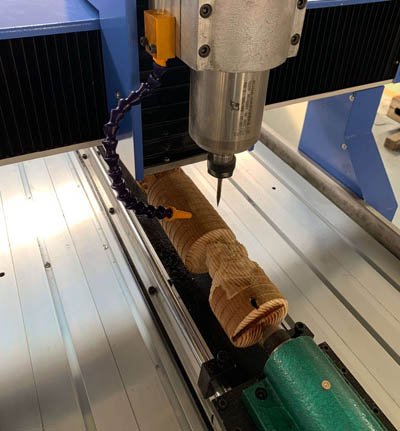

- Rotary Axis: Perfect for processing cylindrical or curved components like instrument necks and scrolls, ensuring precise 360° engraving.

-

Multiple Spindle Configuration: Optional multi-spindle setup allows simultaneous processing of multiple musical instrument parts, significantly enhancing productivity.

- High-Precision Engineering: Delivering consistent quality for complex and intricate patterns on instruments such as violins, guitars, and harps.

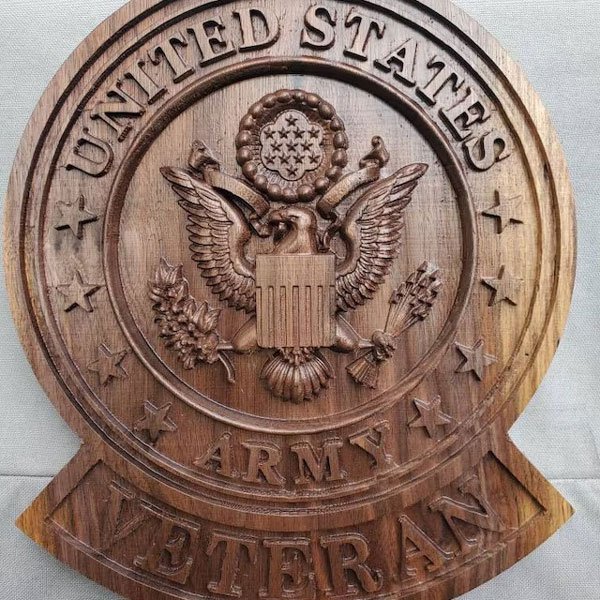

This machine is ideal for producing high-quality wooden instruments with exquisite detail and unmatched efficiency, whether for mass production or customized designs.

Features

The CNC Router for Engraving Musical Instruments is engineered with cutting-edge features to handle various manufacturing processes seamlessly, ensuring precision and efficiency. Key highlights include:

- Multi-Tool Capability: Supports a wide range of tools for cutting, polishing, drilling, and engraving, meeting the diverse requirements of musical instrument production.

- Automatic Tool Changer (ATC): Streamlines workflow by automatically switching between tools for different operations, reducing downtime and enhancing productivity.

- High-Performance Rotary Axis: Enables precise 360° machining, ideal for carving intricate designs on curved or cylindrical components such as necks and scrolls.

- Customizable Spindle Configurations: Offers the flexibility to configure multiple spindles, allowing simultaneous processing of multiple parts to boost efficiency.

- Advanced Software Integration: Compatible with design software like Fusion 360, ensuring smooth execution of complex designs and patterns.

- Durable Construction: Built with robust materials to handle high-volume production while maintaining precision and consistency.

- Soft Wood and solid wood:Soft material handling for delicate tonewoods.

These features make the machine a comprehensive solution for manufacturers seeking to achieve high-quality results in crafting musical instruments with intricate details and superior finishes.

Key Parameters

| Parameter | Details |

|---|---|

| Model | V-SM6090 |

| Working Area | 600mm x 900mm |

| Spindle Power | 3.5KW Air-Cooled Spindle / Multi-heads |

| Control System | Mach3 / DSP/ Fusion 360 Compatible |

| Maximum Speed | 24,000mm/min |

| Precision | ±0.02mm |

| Tool Magazine | 6-Position Automatic Tool Changer(optional) |

| Supported Materials | Rosewood, Maple, Mahogany, Acrylic, Aluminum |

| Voltage | AC 380V / 220V, 50Hz/60Hz |

| Structure | Steel Welded Body with Heat Treatment |

| Dust Collector | Built-in Cyclone Extraction System |

| Rotary | Yes |

cnc-router-6090-project-relief-castle.jpg

Details

The CNC Router for Engraving Musical Instruments is meticulously designed to deliver unparalleled performance, precision, and efficiency, meeting the unique demands of instrument makers around the globe. The machine boasts a standard working size of 130x250 cm, with customizable dimensions available to accommodate specific production requirements.

One of its standout features is the optional multi-spindle configuration, which enables simultaneous processing of multiple wooden workpieces. This design is particularly advantageous for manufacturers aiming to scale production while maintaining consistency across components. Additionally, the integrated automatic tool calibration system ensures seamless and precise tool adjustments, especially useful for delicate operations such as thin sheet cutting or intricate carvings.

Equipped with a high-speed rotary axis, the machine excels at crafting curved and cylindrical components, such as instrument necks and scrolls. The automatic tool changer (ATC) enhances operational efficiency by allowing rapid switching between tools for various processes, including cutting, polishing, and drilling, ensuring an uninterrupted workflow.

Built with high-quality materials and components, the machine guarantees durability and consistent performance even under high production loads. Its compatibility with advanced design software like Fusion 360 further enhances its versatility, enabling the creation of complex and intricate designs with ease.

Whether you are manufacturing violins, guitars, or custom woodwind instruments, this CNC router offers a reliable and comprehensive solution tailored to the exacting standards of modern instrument craftsmanship.

Applications

The CNC Router for Engraving Musical Instruments enables precise manufacturing and engraving of various wooden instrument parts, catering to the needs of instrument makers with efficiency and accuracy.

String Instruments

- Violin: Engraving scrolls, sound holes, bridges, and decorative patterns.

- Cello: Cutting panels, necks, and string slots with precision.

- Viola: Shaping intricate curves and sound holes.

- Double Bass: Crafting large-sized bodies and detailed ornamentation.

- Guitar: Producing necks, fretboards, sound holes, and inlay designs.

- Ukulele: Engraving bodies, bridges, and unique decorative designs.

Keyboard Instruments

- Piano: Cutting soundboards, keys, and decorative components.

- Harpsichord: Creating casings, keys, and intricate carved patterns on the wooden exterior.

Woodwind Instruments

- Wooden Flute: Precisely carving air holes and intricate textures.

- Recorder: Producing various sizes of pipe bodies with fine decorative details.

- Oboe: Shaping curves and tone holes in the body.

Plucked Instruments

- Mandolin: Carving elegant inlay patterns and the body structure.

- Guzheng: Cutting soundboards and string fixtures.

- Pipa: Shaping the neck and string adjustment components.

- Harp: Engraving large body structures, decorative textures, and soundboards.

Percussion Instruments

- Xylophone: Precisely cutting bars for accurate tuning.

- Wooden Drums: Shaping drum shells and surface decorations.

Other Wooden Instruments

- Banjo: Engraving bodies, necks, and decorative inlays.

- Wooden Sax Flute: Precisely processing the body and tone holes.

- Lute: Carving scrolls and intricate ornamental patterns.

- Sitar: Crafting the neck, resonator, and detailed engravings.

With the precise technology of CNC routers, all these instruments can be produced with high quality while significantly improving production efficiency, making it ideal for large-scale production and high-end customization needs.