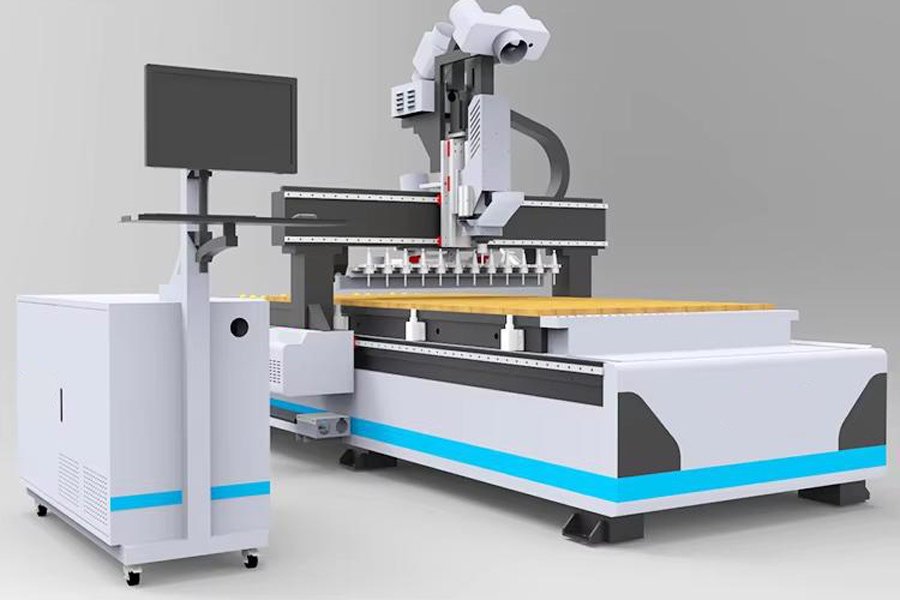

High-Gloss Acrylic CNC Router for Cutting, Engraving, and Polishing with Smooth Finish

Price: $7,800.00

Brand: Versign CNC

In Stock

Model:SKU: V-AR1325

We designed the V-AR1325 High-Gloss Acrylic CNC Router for Cutting, Engraving, and Polishing with Smooth Finish as a one-stop solution for acrylic processing businesses. This versatile machine is capable of cutting, engraving, and polishing acrylic with high gloss and clarity, delivering a smooth finish ideal for high-quality projects. Whether you're working with intricate designs or large-scale production runs, this machine offers outstanding efficiency and precision for all acrylic processing needs.

Inquire NowOverview

We designed the V-AR1325 High-Gloss Acrylic CNC Router for Cutting, Engraving, and Polishing with Smooth Finish as a one-stop solution for acrylic processing businesses. This versatile machine is capable of cutting, engraving, and polishing acrylic with high gloss and clarity, delivering a smooth finish ideal for high-quality projects. Whether you're working with intricate designs or large-scale production runs, this machine offers outstanding efficiency and precision for all acrylic processing needs.

How it Works

The V-AR1325 High-Gloss Acrylic CNC Router achieves precise acrylic cutting and fine polishing (fine finish) through a combination of advanced features and technologies, ensuring that every product comes out with high gloss and perfect surface quality:

- Appropriate Tools and Tool Holders:

The machine uses specially designed cutting tools with high hardness and sharpness, specifically engineered for acrylic materials. These tools reduce heat buildup, preventing deformation due to friction and ensuring a smooth cut. Some examples include:

- Single Flute End Mills

- V-Carve Bits

- Ball Nose End Mills

- Wool Buffing Wheels

The machine comes with a complete set of tools, including diamond acrylic tools, for different cutting, engraving, and polishing needs.

- Precision Cutting Technology:

- High-Precision Spindle: The machine is equipped with a high-precision water-cooled spindle that operates at adjustable speeds for precise cutting. This ensures that burrs and uneven edges are avoided, leaving smooth cuts with no roughness.

- High Speed: The spindle operates at speeds between 10,000–24,000 RPM, ensuring smooth cutting and engraving surfaces, without burrs, while creating fine details.

- High Torque Output: The powerful torque output of the V-AR1325 ensures efficient cutting of thick acrylic, maintaining stability and avoiding uneven processing or incomplete cuts.

- Low Vibration and Low Noise: With a specially designed low-vibration, low-noise spindle, the machine ensures smooth, flawless surfaces during engraving and polishing, ideal for fine acrylic work.

- Cooling Performance: The V-AR1325 is equipped with an efficient air-cooled or water-cooled spindle, maintaining stable temperatures during long, high-load operations, ensuring durability and consistent performance.

- Cutting Parameters: The V-AR1325 High-Gloss Acrylic CNC Router comes with pre-configured cutting parameters, tailored to different types and thicknesses of acrylic. It supports a variety of cutting patterns and designs for smooth and precise cuts.

- Fine Engraving and Detailing:

- Low-Speed, High-Precision Engraving: The machine allows for fine, detailed engraving by adjusting the engraving speed and cutting depth. Low-speed engraving minimizes heat generation, ensuring smoother, more intricate designs.

- Automatic Cutting Depth Adjustment: The machine comes with an automatic depth adjustment feature that precisely controls the cutting depth according to the thickness of the acrylic sheet, avoiding uneven depths and ensuring high precision and fine detailing.

- Automatic Tool Changer (ATC):

The V-AR1325 features an automatic tool changer (ATC), which eliminates downtime and human errors that may occur with manual tool changes. The system can automatically switch between various tools, including roughing tools, finishing tools, and engraving tools. This ensures continuous operation, greater efficiency, and consistent results.

- Efficient Vacuum Table:

- Precise Fixation: Acrylic sheets are securely held in place during processing by a vacuum table, preventing material movement that could impact the quality of the cut or engraving. This guarantees optimal positioning of the acrylic sheet and ensures no cutting errors or surface roughness.

- Reduced Vibration: The design of the vacuum table reduces machine vibrations, providing stable cutting and engraving processes that result in higher-quality, smooth surfaces.

- Advanced Control System:

- High-Precision Control: The machine is equipped with a powerful control system (such as DSP, NCStudio, or MACH3), which precisely manages the path, speed, and depth of each cutting or engraving process. This digital control system ensures that every movement is executed flawlessly, minimizing errors and producing fine, smooth surfaces.

- Offline Operation: The DSP controller supports offline operation, allowing the machine to run without a computer connection, providing more flexibility and ensuring stable, long-term operation.

- High-End Components:

The V-AR1325 High-Gloss Acrylic CNC Router is built with premium components such as precision servo motors or hybrid servo motors, ball screw drives, and square linear rails, which contribute to the machine's stability and accuracy. These high-end parts enhance the overall performance of the machine, ensuring precise acrylic processing results.

With the V-AR1325 High-Gloss Acrylic CNC Router for Cutting, Engraving, and Polishing with Smooth Finish, you can expect superior quality, precision, and efficiency for all acrylic projects. Whether you're working on intricate designs or large-scale production runs, this machine offers exceptional versatility, ensuring top-notch results every time.

Paremeters

| Descriptions | Parameters |

|---|---|

| Model | V-AR1325 |

| Working Area | 1300mm x 2500mm x 200mm |

| Adding | 4*5 drilling package |

| Adding | Machine added the protect cover |

| Spindle Speed | 0-24000/Min |

| Spindle Power | Big Power ATC9KW*1 Water or Air cooling Spindle |

| Tool Magazine | Linear 12 tools position magazine |

| Motor | Big Power Yaskawa or LeadShine 750W or 1500W servo motor |

| Servo Driver | Matching 1500W pure servo motor driver |

| Control System | Intelligent TAI WAN LNC NCStudio control system in Multi Languages |

| Inverter | 11KW E&T Inverter |

| Transmission | X Y axis: Original Taiwan HIWIN 25 Square rail; Z axis: Original TBI 2510 Ball Screw |

| Slider | Original Taiwan HIWIN 25 slider |

| Limit Switch | Dedicated limit switch for ATC CNC Router machine |

| Rack | Good quality Germany imported rack HICK |

| Reducer | Import Japan Shimpo Reducer |

| Vacuum adsorption table | 50MM adsorption hole diameter, PVC pipe connection, sub-regional adsorption table, good airtightness, the board is firmly fixed and does not run off the board |

| Adsorption pump | Super adsorption force Water cycle 7.5KW pump |

| Add braking resistors | More safe |

| Dust collector | Double dust collector bags with 4KW pump |

| Dust removal method | Spindle automatic dust removal and secondary dust removal when pushing materials |

| Empty travel speed | 100000MM/min |

| Maximum Working Speed | 35000MM/min |

| Tool setting method | Automatic tool setting with a tool setting instrument |

| Auto Tool Setting | Auto tool setting function |

| Auto Tool Change | Auto tool change function |

| Auto Position | Two Y axis use the auto positioning bars, X axis use the auto positioning cylinders |

| Auto unloading | Auto unloading function |

| Auto Oil | Auto oil system |

| Electrical components | Genuine original Chint electrical components |

| Cable | Highly flexible shielded drag chain cable |

| Machine Structure | Heavy-duty welded bed, Thickened beam, full sheet metal around. |

| Control Box | Independent and intelligent control box with LED Display Screen |

| Voltage | AC380V / 220V or 480V or others |

| Machine Weight | 2600KG |

| Machine Accessories | Tools, software, wrenches, screwdrivers, brushes, chucks, tool holders, wires, etc. |

Note: These are the default machine specifications. The machine is customizable, and we continually optimize the design. Specifications are for reference only and may change.

Applications of the Eilang CNC Router

The Eilang CNC Router is a versatile and high-performance machine, specially designed for precision acrylic cutting, engraving, polishing, and finishing. Equipped with diamond tools, this machine ensures a flawless, high-gloss finish on acrylic surfaces, making it the perfect solution for industries that demand high-quality, detailed results.

- Acrylic Processing: The Eilang CNC Router is ideally suited for cutting, engraving, polishing, and fine finishing of acrylic sheets, achieving a smooth, transparent, and glossy finish. Its precision ensures clean cuts and intricate engravings, perfect for signage, displays, awards, and artistic designs.

- PVC Cutting and Engraving: This machine is also highly effective for cutting and engraving PVC materials, offering smooth edges and fine details, ideal for both decorative and functional applications.

- Woodworking: The Eilang CNC Router can handle wood cutting, engraving, and polishing, making it a great choice for creating furniture, décor, or custom wooden items with high precision and a perfect finish.

- Other Materials: Beyond acrylic, PVC, and wood, the machine can also work with a variety of other materials such as plastics, composites, and non-ferrous metals, expanding its versatility for different industries and applications.

This multi-material capability makes the Eilang CNC Router a powerful tool for businesses involved in signage, interior design, custom fabrication, and product prototyping.

- Custom signage & displays

- Interior décor & furniture

- Prototyping & product design

- Award trophies & plaques

- Architectural models & mockups

Whether you're working on large-scale production or detailed, intricate designs, the Eilang CNC Router provides the precision, speed, and finish you need for a wide range of materials.