Overview

Common CNC Wood Lathe

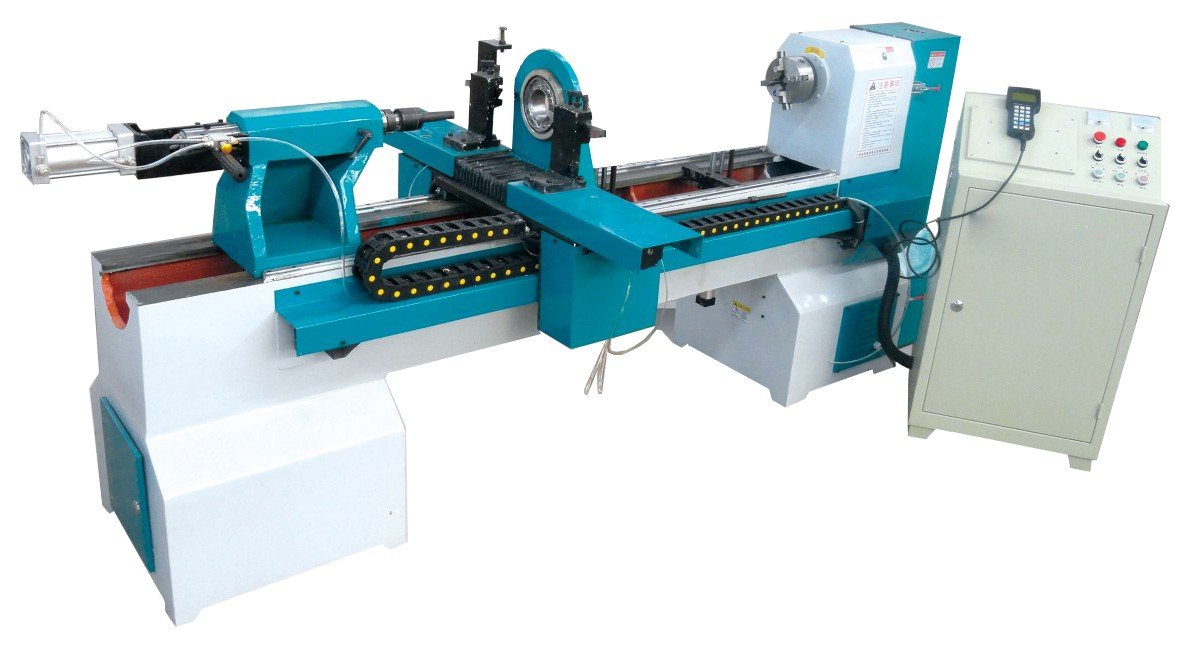

The V-WL1530 Common CNC Wood Lathe is a high-precision, efficient, and reliable lathe designed for solid wood processing. With a heavy-duty whole cast iron structure, it ensures stable operation and long-term durability.

This lathe features a turning diameter range of 20–380mm (0.79”–15”) and a turning length of 100–1000mm (3.9”–39”), making it ideal for furniture legs, spindles, stair components, and other cylindrical wood products.

Equipped with two cutters positioned on either side, one cutter is 0.4” ahead of the other. This design reduces the finishing cutter's cutting depth, enhancing stability. Both cutters work towards the workpiece, minimizing vibration and delivering exceptionally smooth cutting results.

With simple CNC control and robust construction, the V-WL1530 is suitable for both small workshops and larger production environments, achieving high-quality results efficiently and reliably.

Main Parameters

| Model Number | U-MC1035 |

|---|---|

| Spindle / Cutters | 1 spindle, 2 cutters at two sides |

| Turning Diameter | 0.79” – 13.7” (20–350 mm) |

| Turning Length | 3.9”–39” (100–1000 mm) |

| Spindle Motor | 4KW Servo Motor |

| Spindle Speed | 700–4000 rpm |

| Guide Rails | Seamless linear guide rails |

| Drive System | Ball screws drive system |

| Max Feeding Speed | 40 mm/s |

| Processing Accuracy | 0.00125 mm |

| Machine Net Weight | 1600 kg |

| Machine Dimensions (L×W×H) | 3500 × 1500 × 1400 mm |

| Package Dimensions (L×W×H) | 3100 × 1200 × 1600 mm |

| Air Compressor | 0.6–0.8 MPa |

| Voltage | 220V/380V, 3-phase or single-phase, 50–60Hz |

Videos

Watch our CNC Wood Lathe V-WL1530 in action. The following demo videos showcase its turning, carving, and multi-axis machining capabilities, allowing you to see the machine's stability, precision, and efficiency in real production scenarios.

Machine Details

Detailed specifications and key features of the U-MC1035 CNC Wood Lathe.

Turning diameter: 20–380mm (0.79” – 15”)

Turning length: 100–1000mm (3.9”–39”)

Heavy-duty whole cast iron structure.

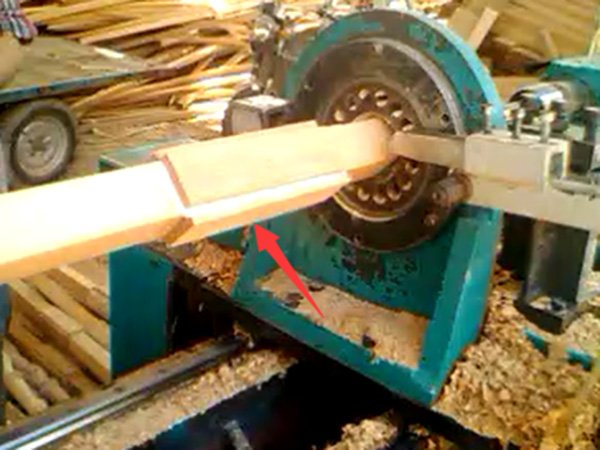

Two cutters at two sides, one cutter is 0.4” ahead of another. Reduces finishing cutter’s cutting depth for stability. Both cutters work towards the workpiece, minimizing vibration and ensuring smooth cutting.

Air-actuated tailstock for precise support of workpieces.

Headstock centering device with four-claw chuck for easy centering of workpieces.

Precision linear rails and ball screws, made in Taiwan.

Precutting cutter for irregular wood billets.

DSP control system: transfer files from PC to handle via flash drive or USB. Processing speed, cutting thickness, and other parameters adjustable directly from handle.

Control system supports .DXF files from various CAD/CAM software. Memory function allows resuming from breakpoints after power loss. Steady rests provided for wood billets smaller than 3.9” (10 cm).

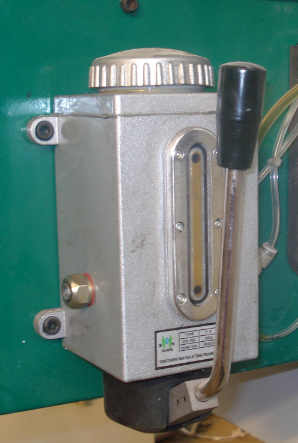

Manual lubrication system allows easy lubrication of guide rails and ball screws.

Our CNC Wood Lathes

Our CNC wood lathes are designed for versatility and precision. The standard models come with a length of 150cm and a turning diameter of 30cm. We offer single-axis, dual-axis, and three-axis machines, as well as fully customized sizes to meet your specific project requirements. These machines can perform a wide range of operations including milling, turning, drilling, and intricate carving, allowing you to produce furniture components, decorative pieces, and artistic woodwork efficiently and accurately.

Whether you need high-volume production or custom artisanal pieces, our CNC wood lathes combine robust construction, reliable performance, and user-friendly control systems to help you achieve exceptional results every time.