Auto Feeding Loading CNC Wood Lathe with Spindle Planer and Polisher

Price: $7,800.00

Brand: Versign CNC

In Stock

Model:SKU: V-AL1530A

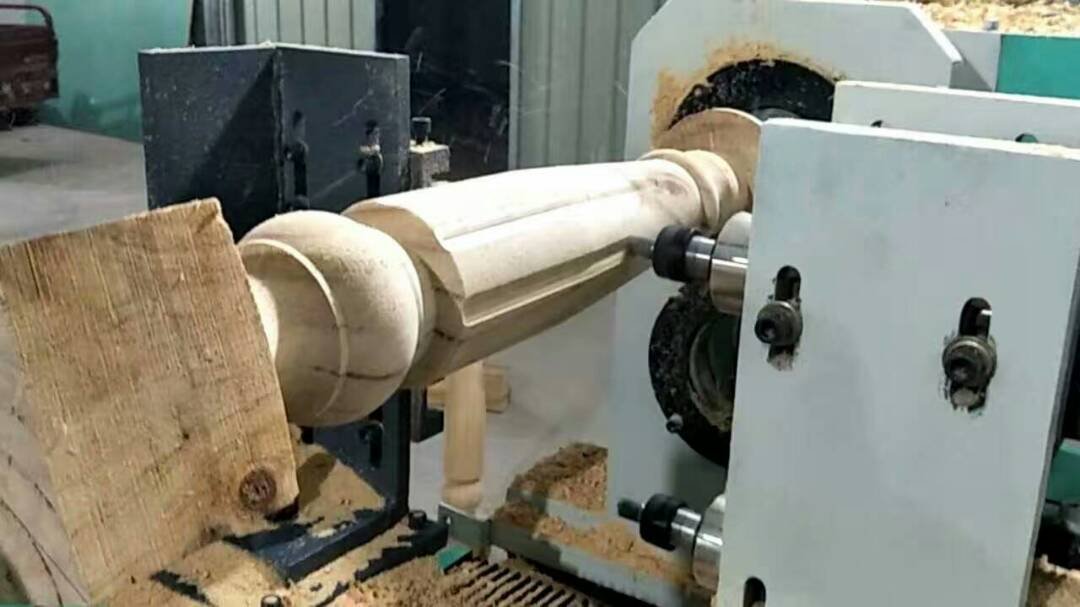

The Auto-Feeding CNC Wood Lathe is a versatile, fully automated machine capable of milling, turning, engraving, drilling, and planing, designed for high-precision production of cylindrical wooden components with minimal manual intervention. With all servo motors and control system, it can expand your woodorking creatition.

Inquire NowOverview

Based on the requirements of the woodworking industry (e.g., stairs, furniture, crafts), characteristics of wood, and processing habits, we have developed the high-efficiency EL-WL1530A Automatic Loading and Unloading CNC Wood Lathe. The LR-1530-A model is capable of processing standardized, uniformly shaped wood products, including cylindrical, conical, arc, and spherical shapes. By changing the program, it can quickly adjust the product's specifications and shape, making it an ideal economic replacement for traditional, low-efficiency wood lathes. This model is especially suitable for small and medium-sized enterprises engaged in batch production of wood products.

The fully automatic loading and unloading CNC wood lathe is equipped with functionalities for shaping, carving twists, slot milling, hollowing, and engraving. Controlled by a CNC system, it operates on the wood's rotating surface without requiring frequent tool changes or manual adjustments. It’s widely used in furniture manufacturing, architectural decoration, and craft production. Ideal for producing various wooden products, such as Roman columns, cylindrical shapes, bowls, vehicle wood crafts, stairway balusters, staircase columns, newel posts, table legs, bar stool legs, and other cylindrical workpieces.

Details

High-Quality Motion System and Components:

The 1530 Auto Feeding CNC Wood Lathe uses variable frequency speed regulation, including a 4-stage 380V variable frequency spindle, an electronic auto-brake inverter, imported ball screws, linear guides, and a stepper motor. These high-precision components significantly enhance the machine's accuracy and efficiency.

Extremely Fast Processing Speed:

Compared to traditional wood lathes, the LR-1530-A model not only saves labor but also greatly improves work efficiency. For instance, processing a wooden column with a diameter of 300mm and a length of 1500mm takes only two minutes.

Ergonomic Design:

An automatic centering system is used when clamping square wood blanks. Before clamping, adjust the height of the support according to the square wood size. The V-shaped groove positions the wood for quick and convenient setup, improving operational safety during turning.

Streamlined Operation:

For various user requirements, we offer a CNC intelligent control system with an industrial one-piece machine control system, eliminating the need for manual input. The system supports USB operation, protects against computer viruses, controls processing speed, and maintains high reliability and efficiency during continuous operation. It’s simple to learn, enabling users to quickly master the machine's operations.

LR-1530-A Automatic Loading and Unloading CNC Wood Lathe Specifications

| Model | LR-1530-A |

|---|---|

| Processing Range | 1500mm * 300mm (customizable) |

| Maximum Processing Diameter | 300mm |

| Maximum Processing Length | 1500mm |

| Control System | Control Panel |

| Frequency Converter | Two sets of Best Brand Frequency Converters |

| Driver | Yako 2D811 Driver |

| Bed Structure | Heavy-duty Integral Casting |

| Transmission Method | High-precision TBI Ball Screw |

| Spindle Motor | 5.5KW Asynchronous Motor |

| Spindle Power | 3.5KW |

| Main Functions | Automatic Loading and Unloading, Shaping, Slotting, Twist Carving, Engraving |

| Spindle Speed | 0-3000 r/min |

| Working Voltage | Three-phase 380V (optional 220V) |

| Weight | 1600kg |

EL-WL1530A Auto Feeding CNC Wood Lathe Installation and Commissioning

- Place the equipment level and secure with anchor bolts. Position the control box appropriately and connect the control wires between the machine and the control box.

- Connect the three-phase power according to electrical safety regulations. Voltage should be 380V ±10V, with each power wire having a minimum cross-sectional area of 2 square millimeters.

- After confirming the machine and control box are normal, power on carefully, staying near the switch to observe for abnormalities.

- Once powered on, set the function to “Manual” to check for any obstructions before operation:

- Test the spindle motor by pressing the “Start” button and adjusting the speed. Ensure “Forward” mode is selected.

- Use the directional buttons to check if the tool carriage and position sensors work correctly.

- Set system parameters by selecting “Setup” and then adjusting key settings such as feed speed, offsets, and tool settings.

- Install the cutting tool securely on the tool holder, typically extending 3-4 cm.

- Load a suitable sample material and follow the instructions to complete the alignment and start trial processing.

Auto Feeding CNC Wood Lathe Applications

Auto feeding CNC wood lathes have a wide range of applications across multiple industries, especially for high-precision woodwork. Here are some key application areas:

- Furniture Manufacturing: Used to produce precise cylindrical components for furniture, such as table legs, chair backs, bed posts, and more, enhancing the aesthetic appeal and consistency of each piece.

- Staircase Production: Commonly applied in the production of staircase parts like balusters, newel posts, and handrails to ensure uniform shape and visual consistency.

- Architectural Decoration: Suitable for crafting decorative wood components, including Roman columns and carved posts, widely used in home and commercial building decor.

- Craft and Artwork: Ideal for producing wooden crafts and decorative items, such as bowls, cups, toy parts, and ornamental boxes, adding creative flair to handmade wooden products.

- Musical Instrument Manufacturing: Utilized in creating round wooden parts for musical instruments, such as drumsticks and flutes, ensuring precision and uniformity.

- Sports and Leisure Equipment: Used to manufacture sports items like baseball bats and pool cues, where balance and precision are critical.

- Mass Production of Small Wood Items: Efficient for producing small wood items in bulk, such as handles, knobs, and hooks, enabling rapid and consistent manufacturing.