Advanced 9KW 12KW Servo Motor CNC Router with Disk ATC

Price: $18,500.00

Brand: Versign CNC

In Stock / Customized

Model:SKU: V-RC1325ATC

Versign CNC proudly presents its Advanced 9KW/12KW Servo Motor CNC Router with Automatic Tool Changer (ATC). This high-performance machine combines speed, precision, and stability, making it the perfect solution for woodworking, metalworking, and a variety of other machining needs.

Inquire NowOverview

Versign CNC proudly presents its Advanced 9KW/12KW Servo Motor CNC Router with Automatic Tool Changer (ATC). This high-performance machine combines speed, precision, and stability, making it the perfect solution for woodworking, metalworking, and a variety of other machining needs.

Designed for professionals, it offers unmatched efficiency and versatility, ensuring exceptional results across all your projects.

Advanced Features

- Powerful Spindle Options: 9KW/12KW HSD brand air-cooled spindle with up to 24,000 RPM for fast and efficient cutting.

- Automatic Tool Changer (ATC): High-speed disc-type system holding up to 16 tools, ensuring seamless tool transitions.

- Servo Motor Precision: High-torque servo motors for smooth, accurate, and stable operation. We use Yaskawa brand servo motors as default.

- Robust Build: Heavy-duty cast iron base and 25mm linear guide rails for enhanced stability and durability.

- Smart Automation: Includes automatic tool setting and optional Wi-Fi connectivity for remote operation.

Versign CNC 9KW 12KW ATC CNC Router Details

- 1. Robust Structure: The machine bed adopts an overall steel structure with seamless welding and tempering treatment, ensuring high rigidity and no deformation.

- 2. High-Speed Precision: Equipped with a Japan Yaskawa servo drive system for fast speeds and high precision.

-

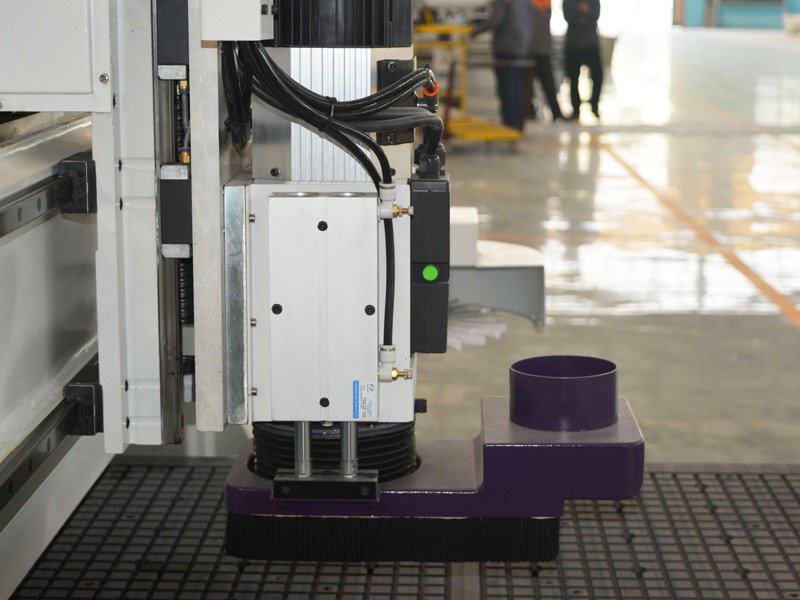

3. Advanced Automatic Tool Changer: Features a follow-up automatic tool changer system with dual tool magazines holding up to 16 tools, saving tool change time and improving production efficiency.

- 4. Imported Guide Rails: Uses Taiwan-imported square rails with double-row four-line ball sliders, offering high load-bearing capacity, smooth operation, high precision, and long service life. Double-nut ball screws ensure precise cutting depth.

- 5. Advanced File Processing: Includes advanced file pre-processing functions to help users promptly correct errors in processing files. Fully compatible with processing codes generated by software like Type3, ArtCAM, Mastercam, and Caxa. Equipped with advanced 3D curve prediction algorithms for smooth polyline processing, ensuring high-speed and precise curve operation.

- 6. Efficient Vacuum Adsorption System: The six-zone vacuum adsorption system is specially designed for soft materials like MDF, allowing the placement of boards of different sizes while maintaining surface flatness. This ensures consistent engraving depth and reduces loading and unloading time for boards. The dust collection system removes sawdust and debris during processing, keeping the worktable clean and indirectly maintaining the equipment.

- 7. Intelligent Control System: Utilizes a new generation Taiwan SYNTEC control system with intelligent boundary protection to prevent mechanical collisions caused by designs exceeding the processing area. Equipped with a handwheel for more convenient and flexible operation. The standalone cabinet and split keyboard design make operations simple and user-friendly, allowing users to quickly master the equipment, making it ideal for beginners.

- 8. Lubrication System: The oil injection system effectively lubricates the machine's transmission components, extending its service life.

- 9. 4 Axis Rotary: Optional rotary for column, square sticks processing.

9KW 12KW ATC CNC Router Technical Parameters

| Specification | Details |

|---|---|

| Model | V-C1325ATC |

| Working Area | 1300*5000*200 mm |

| Precision | Processing accuracy: 0.01 mm |

| X, Y, Z Structure | Z-axis: Imported ball screw; X, Y axes: High-precision helical rack |

| Maximum Rapid Travel Speed | 30,000 mm/min |

| Maximum Working Speed | 20,000 mm/min |

| Spindle Power | Italy HSD 9.0KW 12KW air-cooled spindle |

| Drilling Head | Italy HSD 5+4 drilling head |

| Spindle Speed | 0-24,000 RPM |

| Guide Rails | Japanese automatic lubrication maintenance-free rails, German helical rack |

| Tool Magazine | 8-slot 16-slot disc-type tool magazine |

| Motion Mode | Japan Yaskawa servo system and planetary reducer |

| Working Voltage | AC380V/50Hz or AC380V/60Hz |

| Command Language | G-code |

| Control System | Taiwan SYNTEC (optional Beijing KND or Shanghai Weihong system) |

| Electrical Components | France Schneider electric components and other imported parts for stable performance |

| Net Weight | Approximately 3000 kg |

Applications

- Furniture Manufacturing: Perfect for carving and shaping intricate furniture designs.

- Sign Making: Ideal for cutting and engraving materials such as acrylic and aluminum.

- Metalworking: Excellent for processing soft metals like aluminum and brass.

- Mold Industry: Precise enough for detailed mold-making projects.