4 Axis Rotary CNC Router with DSP A18 Controller for 3D Cutting and Engraving

Price: $6,500.00

Brand: Versign CNC

In Stock

Model:SKU: V-4R1325

The 4-Axis Rotary CNC Router with DSP A18 Controller is a state-of-the-art machine designed for precise and intricate 3D cutting, engraving, and milling applications. With its advanced 4-axis capabilities, it is perfect for

producing complex 3D carvings and designs, especially on cylindrical and irregularly shaped objects. This machine combines high precision with user-friendly features, making it ideal for industries like woodworking, stone

carving, signage, and art.

Overview

The 4-Axis Rotary CNC Router with DSP A18 Controller is a state-of-the-art machine designed for precise and intricate 3D cutting, engraving, and milling applications. With its advanced 4-axis capabilities, it is perfect for

producing complex 3D carvings and designs, especially on cylindrical and irregularly shaped objects. This machine combines high precision with user-friendly features, making it ideal for industries like woodworking, stone

carving, signage, and art.

Advanced Features

-

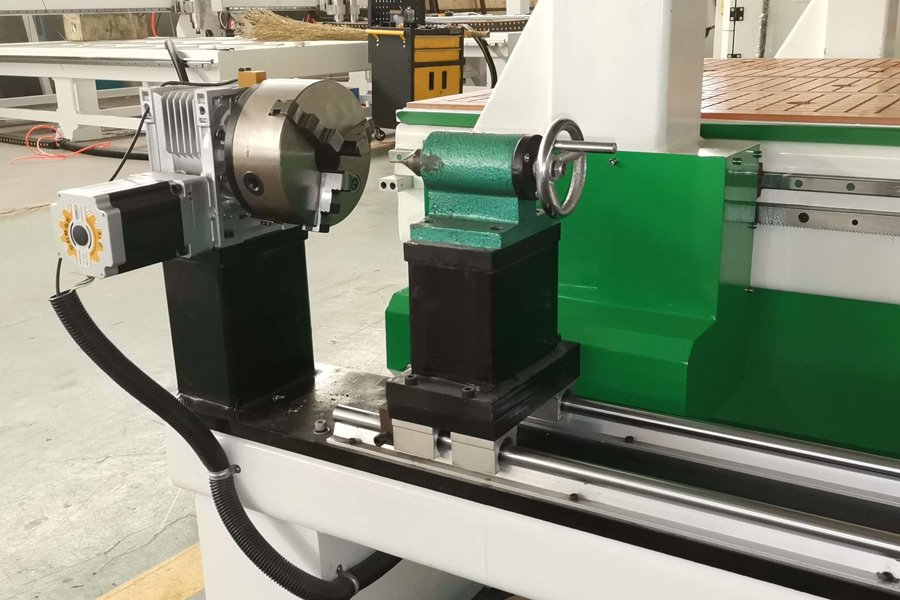

Rotary Axis with Enhanced Stability:

The 4 Axis Rotary CNC Router with DSP A18 Controller for 3D Cutting and Engraving is equipped with a rotary axis capable of handling a maximum diameter of 300mm and a length of up to 3000mm for wood processing.- Featuring a four-jaw chuck and a needle design, the rotary axis ensures greater stability during operation, making it ideal for 3D cutting and engraving.

- The rotary axis is positioned on the side of the machine, allowing for full utilization of the router's worktable without affecting the size of the materials being processed on the flat surface.

-

DSP A18 True 4-Axis Control System:

- The DSP A18 Controller is known for its efficiency and precision in managing multi-axis movement, making it a preferred choice for professional users.

- Unlike simple 3-axis + 1-axis systems, the DSP A18 features true 4-axis control, enabling four-axis synchronous operation (X, Y, Z, and rotary).

- This true 4-axis capability allows for complex 3D engraving, deep carving, and hollow engraving, which cannot be achieved with systems that only project 2D designs onto cylindrical surfaces.

- The DSP A18 controller supports offline operation, meaning the router can function without the need for a continuous connection to a computer, streamlining the workflow and improving operational efficiency.

-

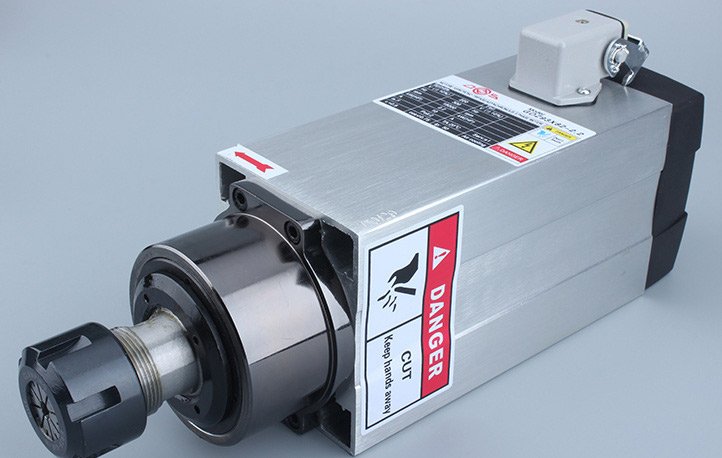

High-Precision Air Cooling Spindle:

- The machine is equipped with a high-performance air-cooled spindle that provides excellent precision and ensures clean, accurate cuts on various materials, including wood, acrylic, plastic, and soft metals.

- Compared to water-cooled spindles, the air-cooled spindle is simpler in structure, easier to maintain, and more adaptable to different environments.

- This type of spindle offers the advantage of quick and effective cooling, which extends the lifespan of the spindle motor and ensures consistent cutting performance.

-

Stable, Heavy-Duty Machine Frame:

- The 4 Axis Rotary CNC Router with DSP A18 Controller for 3D Cutting and Engraving features a heavy-duty bed structure, made from 8-12mm thick cast iron, ensuring high rigidity and excellent stability.

- The design of the machine frame is meticulously crafted to meet the principles of mechanical strength, providing resistance to deformation and allowing for long-term, stable performance.

- The robust frame ensures that the machine maintains accuracy even during high-load and long-duration operations, making it suitable for demanding tasks.

Details

-

Spindle:

- Air-Cooled Spindle: The standard spindle is a 4.5KW air-cooled spindle, equipped with a pure copper coil for strong power and four bearings to provide high torque for stable operation.

-

Available Options: You can choose from a range of spindle power options based on your specific needs:

- 1.5KW, 2.2KW, 3.5KW, 4.5KW, 6KW, 9KW

- Water-Cooled Spindle: Additionally, a water-cooled spindle is available for more demanding applications where a cooling system is necessary to maintain high performance over longer durations.

- Air-Cooled Spindle: The standard spindle is a 4.5KW air-cooled spindle, equipped with a pure copper coil for strong power and four bearings to provide high torque for stable operation.

-

DSP A18 4-Axis Control System:

- Offline Operation: The machine can operate without the need to be connected to a computer, thanks to its DSP A18 control system. This feature allows for greater flexibility and efficiency during operation.

- NC Language Compatibility: The machine uses G-Code (.NC file), the most widely used numerical control (NC) programming language, ensuring compatibility with a wide range of software.

-

Software Compatibility: You can use almost any CAD/CAM software to generate G-Code for the CNC router, including popular options like:

- ArtCAM, CAXA, Mastercam, Powermill, Rhino, VCarve, and many more.

- Optional Control Systems: Other control systems such as MACH3 and NCStudio can also be selected depending on user preferences.

-

High-Performance Stepper Motors:

- Stepper Motor Advantages: The router comes with high-performance stepper motors, which are ideal for driving this machine. Stepper motors offer excellent precision, reliability, and consistent movement in CNC routers, making them well-suited for this system.

-

Advantages of Stepper Motors:

- Precise Movement: Stepper motors provide excellent accuracy for applications that require high precision.

- High Reliability: These motors are known for their durability and ability to handle heavy-duty tasks over long periods.

- Cost-Effective: Stepper motors are often more affordable compared to servo motors, making them an economical choice for many CNC applications.

-

Optional Servo Motor: If preferred, the machine can also be upgraded to Yaskawa brand 750Watt servo motors, known for providing greater speed and higher torque than stepper motors, suitable for

more demanding tasks.

-

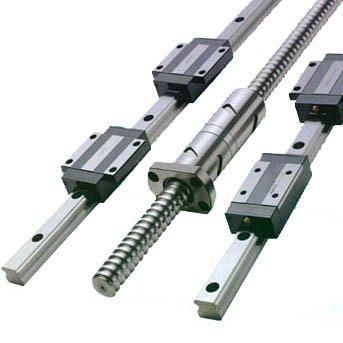

Z-Axis with Ball Screw:

- The 4 Axis Rotary CNC Router with DSP A18 Controller for 3D Cutting and Engraving utilizes a ball screw mechanism for the Z-axis, ensuring high precision and smooth operation during vertical movements.

- The ball screw reduces friction and wear, increasing the longevity of the machine and improving its performance.

-

Quiet Cable Drag Chain:

- The router is equipped with a quiet cable drag chain that protects the cables and ensures smooth movement during operation.

- The drag chain is designed to operate quietly and efficiently, even during long hours of continuous operation, helping reduce wear and tear on cables and minimizing maintenance.

-

Electromagnetic Interference (EMI) Resistant Data and Control Cables:

- The machine is equipped with EMI-resistant cables to ensure stable performance even in environments with potential electrical interference.

- These specially designed cables help prevent signal interference, ensuring that the CNC router operates with high accuracy and reduces the likelihood of errors caused by electromagnetic disruptions.

-

Combined Vacuum Table and T-Slot Table

-

Vacuum Table with Rubber Sealing Ring:

- The vacuum table holds the workpiece securely through suction, which saves labor and time compared to manual clamping methods.

- The rubber sealing ring ensures an airtight seal, optimizing the vacuum pressure for better material fixation.

-

Vacuum Zones: The table is divided into multiple zones, each of which can be independently activated or deactivated with a switch. This allows for targeted clamping, saving energy and

reducing unnecessary suction.

-

Liquid Ring Vacuum Pump:

- The vacuum system is powered by a 5.5kW Liquid Ring Vacuum Pump, which operates at a 33 MBar pressure and delivers an airflow of 230 m³/h. This high-performance pump provides strong, reliable suction to hold the workpieces firmly during machining.

-

Table Surface:

- The vacuum table is constructed from PVC grey plates, offering a durable and easy-to-maintain surface for a wide range of materials.

- The table’s pattern is machined by the CNC wood router itself once the table is installed, ensuring a uniform working surface that allows for precise clamping.

- The CNC machining of the surface provides a replaceable surface design, allowing for easy maintenance or updates as needed.

-

Combined T-Slot Table:

- In addition to the vacuum system, the table features a T-slot surface that allows for additional clamping methods, giving users the flexibility to choose the best workholding method for the job.

- The combination of vacuum and clamping allows for optimal material fixation, reducing the time spent securing workpieces.

-

Vacuum Table with Rubber Sealing Ring:

-

Dust Collector System

-

Dust Collection and Exhaust Control:

- Both cutting and carving processes generate significant dust and debris. Our Dust Collection System uses a combination of a dust hood on the spindle and a vacuum mechanism to capture and manage this dust.

- The dust residue is vacuumed away directly into the dust collector's dust bag, preventing it from scattering into the work environment. This system significantly reduces airborne dust and keeps the work area cleaner.

-

Cleaner Working Environment:

- The dust collection system ensures a cleaner workspace, reducing the accumulation of dust particles that can affect the quality of the work and the health of the workers.

- With effective dust management, the system helps maintain a healthier workforce, reducing respiratory risks and enhancing comfort for operators.

-

Increased Lifespan of Machine Parts:

- By capturing dust and preventing it from entering the machine's mechanical parts, the dust collection system helps extend the lifespan of critical components, such as motors and bearings, by keeping them clean and free from abrasive particles.

-

Blower Motor Specifications:

- Blower Motor Power: 3KW, ensuring sufficient suction power to manage large amounts of dust.

- Air Intake: 2300 m³/hour, providing strong airflow to effectively capture dust and particles from the cutting area.

- Air Speed: 25 meters/second, ensuring high-speed extraction of dust from the work area for quick removal.

-

Dust Hood:

- A dust hood is provided with each CNC wood router to cover the spindle area. This hood connects to the dust collection system, ensuring efficient dust suction during operation.

- The dust hood can also be connected to your own dust collection system, allowing for easy integration if preferred.

-

Dust Hose:

- A soft dust hose with a diameter of 100mm and a length of 4 meters or longer is included when purchasing the dust collector. This hose connects the machine to the dust collection unit, ensuring proper dust extraction during the cutting or carving process.

-

Dust Collection and Exhaust Control:

-

Rotary Axis Design

-

Position and Placement:

- The rotary axis is strategically positioned on the side of the CNC router, which does not interfere with the main worktable used for flat material processing. This layout allows for dual-purpose usage, where the router can work on both flat and cylindrical materials without additional setup time or space limitations.

-

Maximum Processing Diameter:

- The rotary axis supports processing of materials with a maximum diameter of 300mm. This allows for the efficient and accurate engraving and cutting of cylindrical or round-shaped workpieces, such as wood logs, metal rods, or pipes.

-

Maximum Length:

- The rotary axis accommodates materials with a maximum length of 3000mm, enabling the machine to handle long, continuous workpieces, ideal for a variety of projects including large-scale sculptures, signage, or other custom 3D carvings.

-

Precision and Stability:

-

The rotary axis is equipped with a four-jaw chuck and center support to ensure high stability and accuracy during rotation. The center support prevents material deflection, ensuring that the workpiece

remains steady throughout the engraving or cutting process.

-

The four-jaw chuck provides a secure grip on the material, ensuring uniform rotation and preventing slippage during machining. This design ensures consistent precision even on large or irregularly shaped

workpieces.

-

The rotary axis is equipped with a four-jaw chuck and center support to ensure high stability and accuracy during rotation. The center support prevents material deflection, ensuring that the workpiece

remains steady throughout the engraving or cutting process.

-

Enables 3D Processing:

- Unlike traditional systems that simply add a fourth axis to the existing three-axis setup (often only mapping flat designs onto cylindrical shapes), this rotary axis system supports full four-axis motion. 4 Axis Rotary CNC Router with DSP A18 Controller for 3D Cutting and Engraving allows for complex 3D engraving, deep carving, and even hollowing or undercutting, which is not possible with a simple three-axis plus one setup.

- The system’s ability to move in all directions (X, Y, Z, and rotation) gives it full freedom for complex 3D designs, creating deeper, more intricate details that add significant value to the final product.

-

Design for Stability and Flexibility:

- The rotary axis design is optimized for precision machining of both hard and soft materials such as wood, plastic, and certain metals. It is engineered to be highly stable even under extended use, ensuring long-term reliability.

- The ability to rotate the material allows users to engage in multi-axis cutting, providing greater flexibility in project designs.

-

Ease of Integration:

- The rotary axis integrates seamlessly into the machine’s mainframe and can be operated independently or simultaneously with the other axes for fully coordinated movement. It is controlled by the same DSP A18 controller that drives the rest of the machine, allowing for smooth operation and user-friendly programming.

-

Position and Placement:

-

Rotary Alternative Configurations

-

Rotary Axis Positioned at the Front:

-

The rotary axis can be placed at the front of the machine, reducing the overall machine size and footprint. This configuration is ideal for environments where space is limited but full four-axis

functionality is still required. By placing the rotary axis at the front, the machine can maintain its compact design, enabling efficient operations without compromising on capabilities.

- Space-saving: This setup allows for a more compact machine design, ideal for workshops with limited space.

- Easy access: With the rotary axis at the front, the operator has easy access to both the table and the rotating parts, simplifying loading and unloading of materials.

-

The rotary axis can be placed at the front of the machine, reducing the overall machine size and footprint. This configuration is ideal for environments where space is limited but full four-axis

functionality is still required. By placing the rotary axis at the front, the machine can maintain its compact design, enabling efficient operations without compromising on capabilities.

-

Rotary Axis on the Machine Bed (Removable):

- Another flexible option is to mount the rotary axis directly on the machine bed, making it removable when not in use. This option allows the operator to convert the machine from a three-axis router to a four-axis router as needed, providing versatility for different types of projects.

- Modular Design: The removable rotary axis provides the flexibility to use the machine for both flat and cylindrical material processing, based on specific project needs.

- Convenient Storage: When not required for a particular job, the rotary axis can be easily removed and stored, ensuring the machine's table remains free for flat material processing.

-

Customizable Space Usage: With the rotary axis off the bed, the machine can be used for standard cutting and engraving without taking up additional space, making it adaptable to various

workshop requirements.

-

Rotary Axis Positioned at the Front:

-

ATC Functions(Optional):

To meet the demand for more efficient processing, this machine is available with an optional ATC (Automatic Tool Changer) module. With the ATC module, the machine can automatically change tools during the processing, significantly improving production efficiency, reducing tool change time, and enhancing machining accuracy and stability. This makes it ideal for multi-process machining requirements.

Paremeters

| Measurement | Details |

|---|---|

| Working Area (X x Y x Z) | 1300 x 2500 x 200 mm (200 mm is feeding height) |

| Table Size | 1300 x 3000 mm |

| Rotary Diameter | 300 mm, Overall Length 3000 mm |

| Machine Size (X x Y x Z) | 2100 x 3500 x 1500 mm |

| Package Size | 2200 x 3600 x 1700 mm |

| Gross Weight | 1900 kg |

| Voltage | 220V or 380V, 50-60HZ |

| Electrical Power | 10.5 KW (Power rating does not include dust collector and vacuum pump) |

| Software Included | ArtCAM, PowerMill 2018, Vcarve, or UG (optional) |