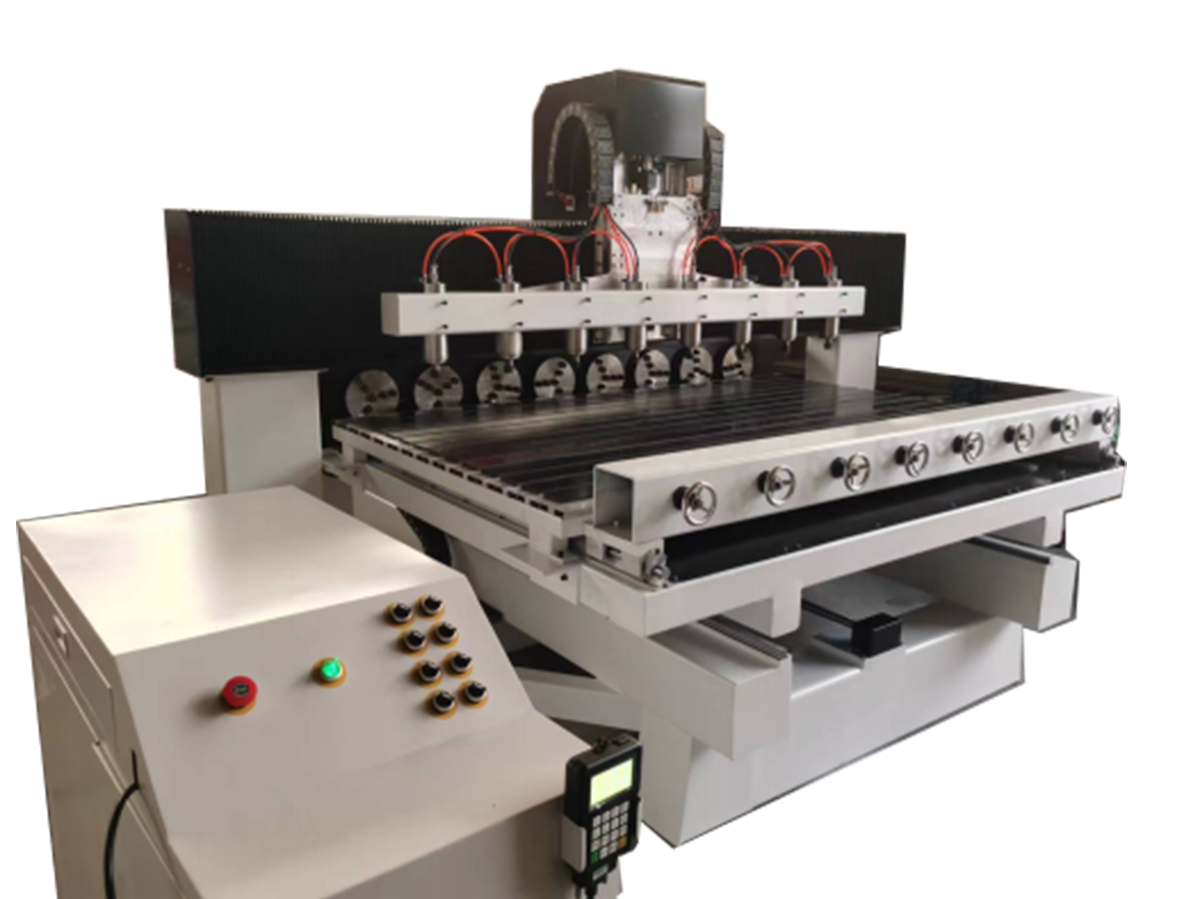

4 Axis CNC Working Center

Precision, Efficiency, and Versatility in One Machine

Our 4 Axis CNC Working Center is engineered for advanced machining applications, combining high precision, rigidity, and multi-dimensional flexibility. With the added fourth axis, this CNC machine allows for rotational processing, enabling complex geometries, intricate carvings, and 3D contouring on a wide variety of materials including wood, plastics, metals, and composites.

Overview

The 4 Axis CNC Working Center is a high-performance, multi-functional machining solution designed for precision, efficiency, and versatility. Equipped with a fourth rotational axis, this machine enables complex 3D contouring and multi-angle processing without repositioning the workpiece, greatly improving productivity and accuracy.

Engineered with a rigid frame, high-quality linear guides, and precision ball screws, the 4 Axis CNC Working Center ensures stable operation, consistent cutting quality, and long-term durability. Its advanced control system provides an intuitive interface for programming, simulation, and real-time monitoring, allowing operators to handle even the most intricate projects with ease.

This machine is suitable for a wide range of materials, including wood, acrylic, plastics, aluminum, and other non-ferrous metals. It excels in applications such as furniture manufacturing, signage production, mold making, and 3D sculpted parts. By reducing manual handling and setup time, it maximizes workflow efficiency and ensures repeatable, high-quality results.

With the 4 Axis CNC Working Center, businesses can achieve professional-grade precision and flexibility, whether producing prototypes, small-batch series, or full-scale manufacturing runs. Its combination of performance, reliability, and versatility makes it a trusted choice for modern CNC machining operations.

Parameters

| Machine Name | LB12020-8 Rotary Axis |

|---|---|

| Net Size (L×W×H) mm | 2200 × 2200 × 2100 |

| Working Stroke (X×Y×Z×A) mm | 500 × 1200 × 200 × 200 |

| Voltage | 3ph 380V / 50Hz |

| Spindle Brand | China HQD |

| Spindle Power | 4.5KW ER25 |

| Spindle Cooling | Air Cool |

| Spindle Speed | 0-18000 rpm |

| Tool Diameter | Ø3.17mm - Ø12.7mm |

| Drive System | Servo |

| Drive Motor | Delta 1.5KW |

| Drive Drivers | Delta 1.5KW |

| Inverter Brand | Fuling |

| Inverter Power | 11KW |

| Control Unit | NK280 |

| Rails | Hiwin HG30 |

| Screw Rod | TBI (Made in Taiwan) |

| Table | Rotary Axis |

| Lubrication | Manual Oil Pump |

| Reducers | Shimpo Reducers |

| Racks | 2M Helical Rack |

| Electronics | Schneider |

| Frame | Heavy Duty |

| Gantry | Welded Tubular |

| Standard | CE |

| Software | Powermill |

| Precision | ±0.05mm |

| Max No-Load Speed | 25 m/min |

| Working Speed | 15 m/min |

| CNC Code | NC, U00, MMG, ENG, TXT |

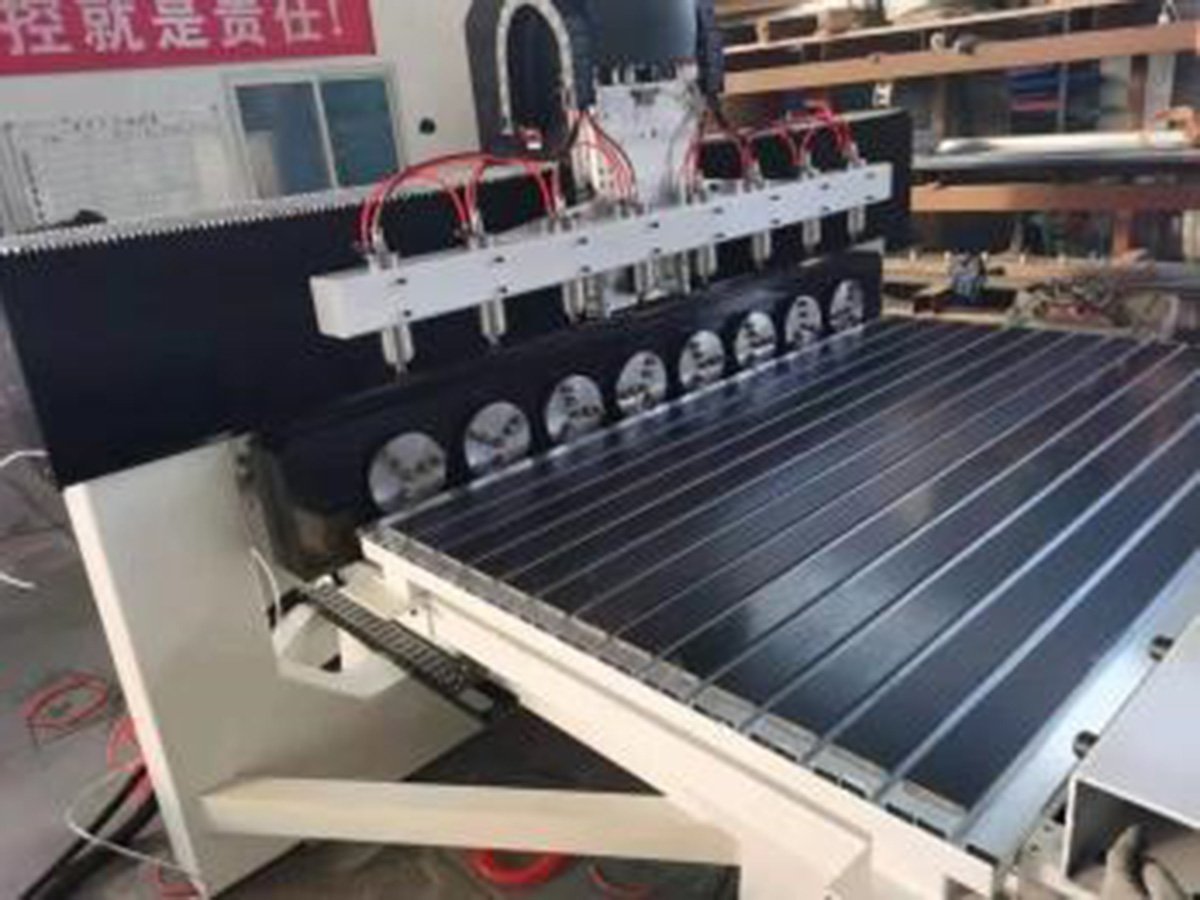

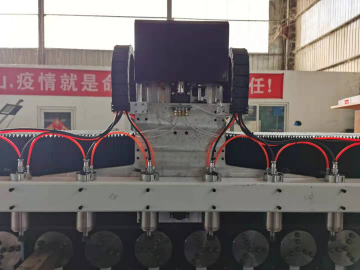

Photos

Take a closer look at our 4 Axis CNC Working Center in action. Precision, quality, and versatility captured from every angle.

Advanced Features

Our 4 Axis CNC Working Center is built with cutting-edge technology to ensure high performance, precision, and durability.

High Rigidity

The heavy-duty welded frame and robust gantry design provide exceptional rigidity for precise machining and minimal vibration.

Stable Operation

Precision linear guides, TBI screws, and high-quality reducers ensure smooth and consistent motion even during high-speed operations.

Multi-Material Capability

Efficiently processes wood, plastics, acrylic, aluminum, and other non-ferrous materials with high repeatability.

High Precision

Achieves ±0.05mm precision for intricate designs, 3D carving, and complex multi-axis machining projects.

Advanced Control System

User-friendly CNC interface allows easy programming, simulation, and monitoring for both beginners and professionals.

Efficient Workflow

Reduces manual handling, shortens setup time, and enhances productivity with automatic multi-axis rotation and repeatable positioning.

Applications

The 4 Axis CNC Working Center is ideal for a wide range of industries and manufacturing needs.

- • Furniture manufacturing

- • Signage and advertising panels

- • 3D carving and sculpting

- • Molds and prototyping

- • Acrylic and plastic processing

- • Custom parts for industrial applications