Best DSP Servo type 3/4 Shift Phenumatic CNC Router

Price: $7,600.00

Brand: Versign CNC

In Stock

Model:SKU: V-3SC1325 V-3CS1530

The 3 Pneumatic Spindles CNC Nesting Machine is a high-performance solution designed for cabinet making, panel processing, furniture production, and other woodworking applications. Featuring three pneumatic spindles, the machine allows users to switch tools quickly without a tool changer, reducing downtime and improving production efficiency.

Inquire Now3 Pneumatic Spindles CNC Nesting Machine (V-3SC1530 / V-3SC1325)

The 3 Pneumatic Spindles CNC Nesting Machine is a high-performance solution designed for cabinet making, panel processing, furniture production, and other woodworking applications. Featuring three pneumatic spindles, the machine allows users to switch tools quickly without a tool changer, reducing downtime and improving production efficiency.

With its heavy-duty frame, advanced CNC control system, and compatibility with leading CAD/CAM software, this machine ensures accuracy, stability, and long-term reliability. The V-3SC1530 model provides a larger working area (1500×3000mm), while the V-3SC1325 offers a compact size (1300×2500mm), giving manufacturers the flexibility to choose the right fit for their workshop.

- ✅ Multi-spindle design for cutting, engraving, drilling & slotting

- ✅ High nesting efficiency – saves time & material

- ✅ Robust structure for vibration-free operation

- ✅ Cost-effective alternative to ATC machines

Advanced Features of 3 Pneumatic Spindles CNC Nesting Machine

Triple Spindle High Efficiency

The machine is equipped with three independent pneumatic spindles, which can automatically switch between different tools such as cutting blades, drilling bits, and engraving tools. This eliminates the need for manual tool changes, greatly reducing downtime and improving productivity. In large-scale furniture manufacturing, where multiple machining processes are required on a single sheet, the multi-spindle design ensures smooth workflow, higher precision, and optimized efficiency. It is particularly effective for cabinet doors, wardrobes, panel furniture, and customized production lines.

Heavy-Duty Rigid Frame

The base and gantry are constructed from high-strength welded steel, which undergoes annealing and vibration stress relief to remove internal stress. This guarantees long-term mechanical stability and reduces deformation during years of high-intensity operation. The rigid frame not only ensures smoother motion but also reduces vibration during high-speed cutting, which is essential for maintaining consistent cutting quality. Customers benefit from a machine that can handle heavy-duty production cycles without compromising on accuracy or reliability.

Smart CNC Control System

The machine adopts a professional CNC nesting control system with advanced motion algorithms and high-speed data processing capabilities. It supports multiple file formats from mainstream CAD/CAM software, ensuring seamless workflow integration. The user-friendly interface allows operators to easily manage nesting layouts, material utilization, and tool paths, while reducing programming errors. In addition, the controller provides real-time monitoring, fault detection, and automatic optimization of cutting sequences, helping customers save materials and maximize efficiency.

Vacuum Table with Strong Suction

Equipped with a high-power multi-zone vacuum adsorption table, the machine ensures stable fixation of various sheet materials such as MDF, particle board, plywood, PVC, and acrylic. Even during high-speed cutting and drilling, the sheets remain firmly secured, preventing movement and ensuring consistent edge quality. The multi-zone design allows the operator to activate different suction areas independently, enabling flexible machining of full-size panels or smaller workpieces. This feature reduces waste, improves accuracy, and increases production efficiency, making it highly suitable for modern panel furniture production.

Key Features of 3 Shift CNC Router

High Precision & Stability

Built with a cast-iron structure, the 3 Shift CNC Router ensures long-term mechanical stability and minimizes vibration during high-speed machining. With a working accuracy of <0.03mm/300mm, it delivers excellent precision for detailed engraving, cutting, and drilling tasks. This robust design makes it ideal for industries demanding consistency, such as furniture, signage, and mold making.

Efficient Working Area

The machine offers a generous working area of 1300 × 2500 × 200 mm, with models available in 1530 and 2030 sizes for larger panels. Combined with an aluminum T-slot table with PVC protection, operators can easily secure materials of different thicknesses and dimensions. This makes the 3 Shift CNC Router a versatile choice for processing MDF, plywood, acrylic, PVC, and other sheet materials.

Powerful Spindle & Drive System

Equipped with 3 × 3.5kW air-cooled spindles, the 3 Shift CNC Router ensures continuous operation with reliable cooling performance. The spindles support speeds up to 24,000 rpm, enabling both rough cutting and fine engraving. The machine uses Taiwan TBI ball screws (1605 for X/Z, 2510 for Y axis) and linear square guide rails, ensuring smooth transmission and long service life.

Smart Control & Software Compatibility

The router is powered by the Ncstudio control system, offering user-friendly operation, stable performance, and high efficiency. It supports standard G-code along with multiple formats (*.u00, *.mmg, *.plt), making it compatible with Type3, Castmate, CorelDRAW, AutoCAD, ArtCAM, and other CAM/CAD software. This flexibility allows easy integration into existing production workflows.

Reliable Motor & Drive System

The CNC router is driven by 86BYG-450B stepper motors paired with Leadshine MA860H drivers, providing strong torque, accurate positioning, and smooth motion. With a traveling speed up to 7,000 mm/min, it is well-suited for both high-speed cutting and precise detailed work. This ensures stable performance even during intensive production runs.

Advanced Tool Sensor

The integrated automatic tool sensor simplifies calibration and tool setting, reducing setup time and improving accuracy. This feature is especially beneficial in production environments requiring frequent tool changes, ensuring consistent cutting depth and reducing the risk of human error.

Detailed Features of 3 Shift CNC Router

HIWIN / TBI Linear Guide Rails

The machine adopts HIWIN or TBI square linear guide rails, ensuring high load-bearing capacity, smooth movement, and long-term durability. This guarantees machining precision even under high-speed and heavy-duty operations, making it suitable for demanding industrial applications.

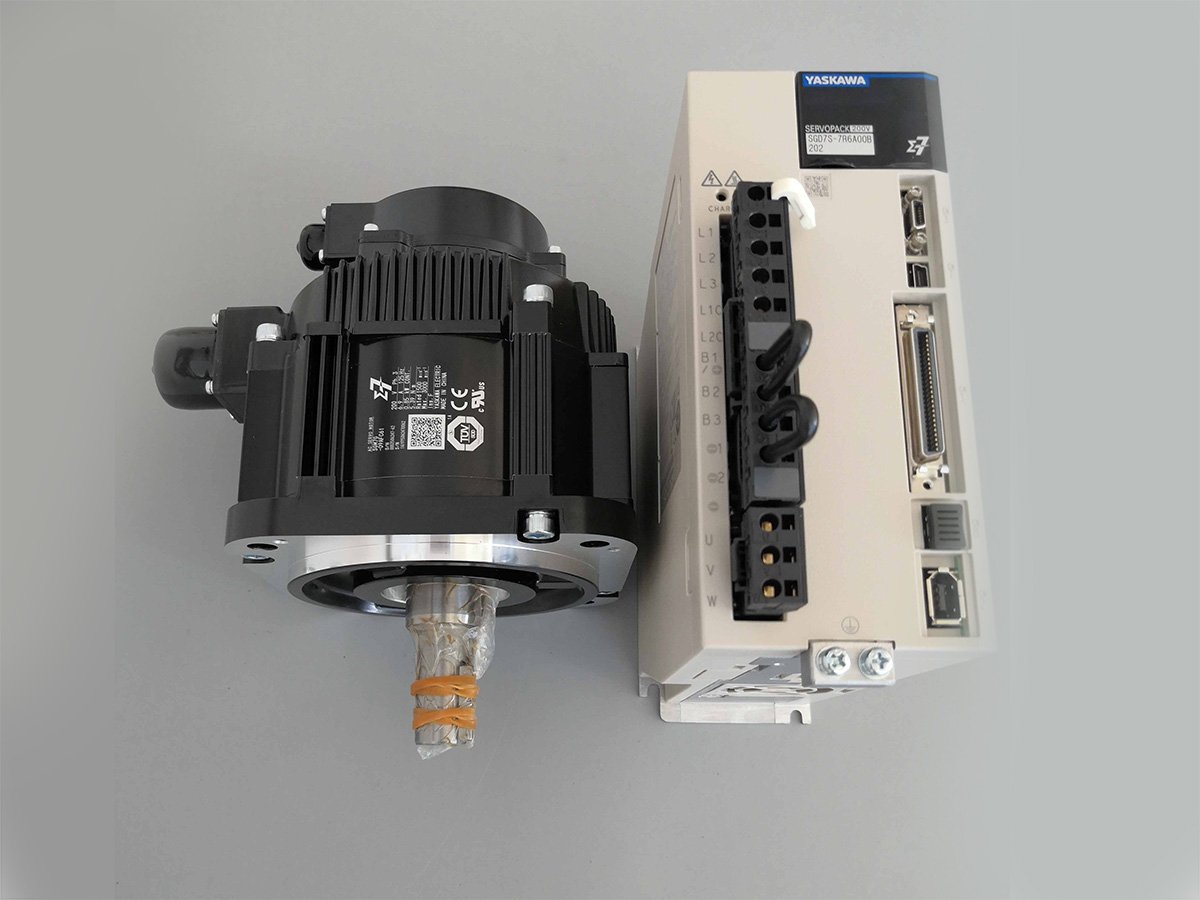

Yaskawa 1000W / 1.5kW Servo Motors

Equipped with Japan Yaskawa servo motors, the Versign CNC router 3 Shift offers excellent stability, fast response, and accurate positioning. With 1000W and 1.5kW options, it provides strong power for heavy-duty cutting and ensures consistent performance in long production runs.

HSD High-Power Spindle

The machine is equipped with an Italian HSD spindle, available in 9kW and 12kW versions. Known for reliability and long lifespan, the HSD spindle provides powerful cutting ability and can handle both delicate engraving and heavy-duty milling tasks with ease.

Reinforced Machine Frame

The frame undergoes stress-relief treatment and precision planing, ensuring long-term structural stability without deformation. This robust construction reduces vibration during machining, enhances accuracy, and guarantees reliable operation in continuous production environments.

Automatic Tool Calibration

Integrated automatic tool sensor ensures precise tool length detection, reducing setup time and improving machining accuracy. This feature increases efficiency and consistency, especially in multi-tool operations.

Advanced Dust Collection System

Equipped with a high-efficiency dust extraction system, the machine keeps the working area clean and ensures operator safety. This not only extends tool life but also improves product surface quality by preventing debris interference.

Intelligent Control System

Powered by a professional CNC control system, the 3 Shift CNC router provides stable performance, fast data processing, and compatibility with multiple CAD/CAM software. This ensures smooth operation even for complex machining jobs.

Safety & Reliability

The machine integrates emergency stop switches, overload protection, and flame-retardant cable covers, ensuring operator safety and stable machine performance. Built with industry-standard electrical components (Schneider, Omron), the cnc router guarantees durability and safety in any working condition.

Applications of 3 Shift CNC Router

The 3 / 4 Shift CNC Router is a versatile machine widely used across multiple industries. With its high precision, strong spindle power, and durable structure, it is ideal for woodworking, signage production, furniture manufacturing, and non-metal material processing. Below are some of the main application areas:

Woodworking & Furniture

Perfect for making solid wood doors, cabinets, tables, chairs, and decorative panels. The 3 Shift CNC Router ensures smooth cutting and precise engraving, ideal for both mass production and customized furniture.

Advertising & Sign Making

Widely used in acrylic cutting, PVC board processing, 3D lettering, and decorative sign production. Delivers excellent edge finishing and high-quality engraving results.

Non-Metal Material Processing

Capable of processing plastic sheets, composite panels, acrylic, MDF, and foam boards. Ideal for packaging, mold making, and decorative architectural elements.

Artistic & Industrial Design

Used in artistic engraving, 3D relief carving, and industrial prototypes. The high accuracy and stable performance make it suitable for creative industries, delivering detailed and professional results.

Frequently Asked Questions (FAQ)

- Asia: 7–15 days

- Europe: 25–35 days

- South America: 35–45 days

- Africa: 35–50 days

- English user manual & video tutorials

- Online remote training (via video call, WhatsApp, or TeamViewer)

- Optional engineer overseas service (extra cost)

- 3.5kW – 6kW air cooling spindle (standard models)

- 9kW – 12kW HSD Italian spindle (for professional heavy-duty use)

- HIWIN or TBI linear square guide rails – precision and durability

- Yaskawa servo motors (1000W / 1500W) – stable and powerful drive system

- Ball screw transmission – high accuracy with minimal backlash

- 2 years warranty for the machine

- 1 year warranty for spindle and electrical parts

- Lifetime online support Spare parts are available at cost price after the warranty period.

- Clean dust and debris after each use

- Lubricate guide rails and ball screws regularly

- Check spindle collet and tool holder

- Inspect cables and connections to avoid wear